It goes beyond the basics of simply firing clay and involve a deep understanding of temperature controls, firing schedules, and atmosphere manipulation. Professionals often use computer-controlled kilns to achieve precise results, manipulating variables like oxidation or reduction atmospheres during the firing process. Specialized techniques such as salt firing, soda firing, or wood firing require advanced knowledge of fuel types, flame control, and the impact of different materials like sodium chloride or wood ash. These operations demand thorough safety measures, including proper ventilation and use of personal protective equipment, to mitigate risks like exposure to harmful fumes or thermal burns. Mastery of advanced kiln operations opens up a world of artistic possibilities but comes with its own set of challenges and responsibilities.

- Temperature Control – Accurate regulation of kiln temperature, often managed through computerized systems, for precise firing outcomes.

- Firing Schedules – Detailed plans that outline the rate of temperature increase and duration at peak temperatures, customized for specific projects.

- Atmosphere Manipulation – Control of the kiln’s internal atmosphere, such as oxidation or reduction, to achieve desired glaze and clay body effects.

- Specialized Firing Techniques – Use of methods like salt firing, soda firing, or wood firing, each requiring unique skills and knowledge.

- Fuel Types – Understanding the different types of fuels like gas, wood, or electricity, and their impact on the firing process.

- Flame Control – Mastery in adjusting the flame’s characteristics to affect the atmosphere and temperature within the kiln.

- Ventilation – Ensuring proper air flow within the kiln and the surrounding area to remove harmful fumes and maintain a safe workspace.

- Personal Protective Equipment (PPE) – Use of safety gear like heat-resistant gloves, face shields, and respirators to protect against potential hazards.

- Maintenance and Calibration – Regular checks and adjustments to ensure the kiln is operating efficiently and accurately.

- Safety Protocols – Established guidelines and emergency procedures to handle issues like thermal burns, gas leaks, or electrical malfunctions.

1 Temperature Control

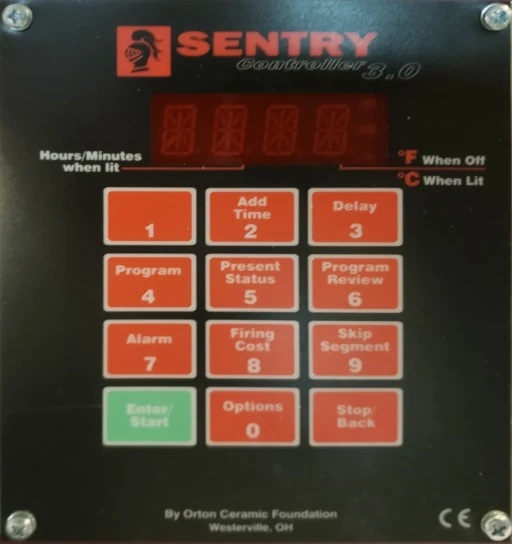

Paragon Kiln 12-KeySentry Programmable Controller1

- 12-Key Interface: A user-friendly keypad.

- Programmable: Allows you to set custom firing schedules, including ramp rates, hold times, and target temperatures.

- Multiple Programs: Capability to store multiple firing programs.

- Safety Features: May include error detection, over-temperature shutoff, and other safety measures.

- Data Logging: The ability to log firing data for future reference or analysis.

Why It’s More Than Just Setting a Dial

In advanced kiln operations, temperature control is like the bread and butter of the whole thing. You’re not just turning a dial and hoping for the best. No, we’re talking about precise, calculated temperature regulation. Often, this is done using computerized systems that let you set specific firing schedules, peak temperatures, and even control how fast the kiln heats up or cools down.

Types of Temperature Control Systems

- Manual Kilns

These are the OGs of the pottery world. But even with a manual kiln, you can use pyrometric cones to gauge the heat work in the kiln, although it’s less precise. - Programmable Controllers

These are digital systems that allow you to input specific temperature settings and firing curves. It’s like setting a cooking recipe for your pottery. - PID Controllers

These go a step further by continuously adjusting the kiln’s temperature to minimize errors. PID stands for Proportional-Integral-Derivative, and these controllers are all about accuracy.

Why It Matters

- Consistent Results

Proper temperature control ensures that each firing yields consistent results, which is crucial if you’re working on a series or simply want to replicate past successes. - Material Safety

Different clays and glazes have specific temperature ranges where they behave best. Going too hot or too cold can result in defects or even safety hazards like cracks or explosions. - Energy Efficiency

Accurate temperature control also means you’re not wasting energy by overheating or underheating the kiln, which is both eco-friendly and budget-friendly.

2 Firing Schedules

Why It’s Like a Roadmap for Your Kiln

So let me chat a little about firing schedules. Think of it as your kiln’s GPS, guiding it through the twists and turns of temperature changes. It’s not just about reaching the peak temperature; it’s also about how quickly you get there and how long you hang out at that level. Different projects need different routes, and a well-planned firing schedule is what makes it all come together.

Types of Firing Schedules

- Ramp-Hold Schedules

This is where you set a rate of temperature increase and then hold it steady for a period. It’s like accelerating to highway speed and then going on cruise control. - Step Scheduling

This is more like a staircase, where you raise the temperature, hold, then raise it again. It’s great for complex projects that need multiple temperature plateaus. - Custom Schedules

For those unique, one-of-a-kind projects, you might even design a custom schedule that mixes elements of ramp-hold and step scheduling. It’s like drawing your own map.

Why the Details Matter

- Material Behavior

Different materials react differently to heat. Some might need a slow, gradual increase, while others can handle a quick ramp-up. A good schedule accounts for these nuances. - Energy Efficiency

An efficient schedule will get you the results you want without wasting energy. That’s good for the planet and your wallet. - Quality Control

The right firing schedule can make or break your final product. Uneven heating or cooling can lead to cracks, warping, or even breakage. - Reproducibility

Once you nail a schedule that works, you can use it again for similar projects. It takes the guesswork out of the equation for future firings.

3 Atmosphere Manipulation

It’s Not Just Hot Air, Seriously

I’ll get after it and dive into atmosphere manipulation in the kiln. This is where pottery starts to feel a bit like science fiction. You’re not just heating things up; you’re actually changing the environment inside the kiln. This could be an oxidation atmosphere, where there’s plenty of oxygen, or a reduction atmosphere, which is low on oxygen. Each has a dramatic effect on how your glaze and clay body turn out.

Types of Atmospheres

- Oxidation Atmosphere

This is when there’s ample oxygen inside the kiln. It’s most commonly used because it’s easier to control and tends to produce brighter, glossier finishes. - Reduction Atmosphere

Here, you’re intentionally limiting the oxygen, usually by tweaking the fuel-to-air ratio. This results in earthier, more matte finishes and can even alter the clay body’s color. - Neutral Atmosphere

This is the Goldilocks zone where you’re not adding or taking away oxygen. It’s a balanced environment that’s harder to maintain but can offer unique results.

Why You’d Want to Fiddle with Atmosphere

- Glaze Effects

The atmosphere can make the same glaze look entirely different. Oxidation might make a glaze turn bright blue, while reduction could change it to a soft green. - Clay Body Changes

In a reduction atmosphere, iron in the clay can react differently, giving you a completely different color or texture in the finished piece. - Artistic Flexibility

Once you get the hang of it, atmosphere manipulation allows you to experiment in ways that simple temperature control can’t offer.

4 Specialized Firing Techniques

Beyond the Basics – Where Art Meets Science

So, you are telling me you’ve got your basic firing down and you’re looking to jazz things up a bit? Welcome to the world of specialized firing techniques. Whether it’s salt firing, soda firing, or wood firing, each method is its own little universe of techniques, rules, and surprises. It’s like cooking; once you master the basics, you can start experimenting with spices and flavors.

The Different Flavors of Specialized Firing

- Salt Firing

This involves adding salt into the kiln at high temperatures. The salt vaporizes and creates a glaze on the pottery. It’s a bit unpredictable but can produce some really unique textures and colors. - Soda Firing

Similar to salt firing, but here you’re using soda ash or sodium bicarbonate. It produces a more subdued, often glossy surface, and you have to be super cautious with ventilation because the fumes can be corrosive. - Wood Firing

This is the old-school way, using wood as the fuel. The ash from the wood creates natural glazes, and the flames can add unique markings to the pieces. It’s labor-intensive but oh-so-rewarding.

Why Go the Extra Mile?

- Unique Outcomes

These techniques offer results you just can’t get with standard electric or gas kilns. We’re talking textures and colors that are truly one-of-a-kind. - Skill Development

Mastering these techniques really elevates your pottery game. It’s like adding some advanced moves to your dance routine. - Community and Collaboration

Especially with techniques like wood firing, it’s often a community effort. You learn from others, share the workload, and celebrate the results together.

5 Fuel Types

It’s Not Just About Making Things Hot

Believe it or not, the kind of fuel you use in your kiln is a big deal. Gas, wood, electricity, they’re not just interchangeable sources of heat. Each one has its own quirks and advantages that can seriously affect how your project turns out.

The Big Three – Gas, Wood, Electricity

- Gas Kilns

These are popular because they can reach high temperatures and offer good control. Gas kilns are often used for reduction atmospheres, which is kinda their claim to fame. - Wood Kilns

These are the old souls of the pottery world. They’re labor-intensive and need constant monitoring, but the natural ash and flame effects are totally worth it. - Electric Kilns

These are the plug-and-play options, perfect for beginners or those who want precision. They’re generally used for oxidation firings and are super easy to control.

What’s at Stake?

- Temperature Range

Different fuels can reach different temperatures. Gas and wood can go super high, while electric kilns might have a lower ceiling. - Atmosphere Control

As I mentioned, gas is great for reduction, and electric is generally used for oxidation. Wood is a wild card that can offer a bit of both, depending on how you manage it. - Cost and Convenience

Electric kilns are generally cheaper to operate and easier to maintain. Gas and wood kilns, while offering unique benefits, can be pricier and more labor-intensive. - Environmental Impact

Electric kilns can be more eco-friendly, especially if your electricity comes from renewable sources. Gas and wood have a bigger carbon footprint, so that’s something to consider.

6 Flame Control

Flame control, if you’ve ever sat around a campfire trying to roast the perfect marshmallow, you’ll get the importance of flame control. Except here, it’s not s’mores at stake, it’s your art. Whether you’re using gas or wood as fuel, the ability to adjust the flame’s characteristics is key to achieving specific atmospheres and temperatures in the kiln.

The Anatomy of a Flame

- Primary Air

This is the air that mixes with the fuel before ignition. Too little and your flame will be smoky; too much and it’ll be too hot and fast. - Secondary Air

This is the air that mixes with the flame after ignition. It’s what you adjust to switch between reduction and oxidation atmospheres. - Flame Shape and Color

The flame’s shape can tell you a lot about what’s happening inside the kiln. A blue flame is hotter and indicates complete combustion, while a yellow flame is cooler and might mean incomplete combustion.

The Nitty-Gritty of Flame Control

- Achieving Atmospheres

By adjusting the primary and secondary air, you can control whether the kiln is in an oxidation or reduction state, each of which affects your pottery differently. - Temperature Regulation

A consistent flame leads to consistent temperatures, which is crucial for any firing schedule you might be following. - Safety Measures

Proper flame control also minimizes risks. An unstable flame can lead to backdrafts or incomplete combustion, both of which are safety hazards.

7 Ventilation

Why You Can’t Just Wing It with a Window Fan

Okay, let me talk about ventilation. No, it’s not the most glamorous part of pottery, but trust me, it’s one of the most crucial. We’re talking about ensuring proper air flow in both the kiln and the surrounding workspace. Why? Well, a bad ventilation setup is like cooking in a kitchen filled with smoke; it’s uncomfortable and downright dangerous.

Types of Ventilation Systems

- Kiln Vents

These are built directly into the kiln and are designed to remove harmful fumes. They’re your first line of defense and an absolute must-have. - Local Exhaust Ventilation

This is like having a targeted fan that sucks away the bad stuff right where it’s being produced. Super useful when you’re glazing or doing any chemical work. - General Ventilation

Think of this as the big-picture air flow in your studio. It could be as simple as a ceiling fan or as advanced as a full HVAC system.

Why Ventilation is a Big Deal

- Health and Safety

Poor ventilation can lead to a build-up of toxic fumes and dust. Long-term exposure is bad news for your lungs and overall health. - Quality of Work

Proper ventilation also affects the firing process. Bad air flow can mess with your kiln’s atmosphere and temperature, leading to inconsistent or undesirable results. - Compliance and Regulations

Many places have strict rules about ventilation in spaces where potentially hazardous materials are used. So, proper ventilation isn’t just a good idea; it’s often a legal requirement.

8 Personal Protective Equipment (PPE)

The Gear That Stands Between You and Oops Moments

PPE is like the superhero costume for potters. No, it won’t give you superpowers, but it will protect you from a whole lot of potential hazards in the studio. We’re talking heat-resistant gloves, face shields, respirators—the whole nine yards.

The Must-Have Gear

- Heat-Resistant Gloves

These are lifesavers when you’re dealing with hot kiln shelves or freshly fired pieces. They’ll keep you from yelling out every curse word you know because you accidentally touched something hot. - Face Shields and Safety Glasses

These protect your eyes and face from flying debris, especially when you’re chipping away at a piece or working with tools. - Respirators

Not to be confused with simple face masks. Respirators actually filter out harmful particles from the air, and trust me, your lungs will thank you.

Why You Shouldn’t Skip on PPE

- Safety First

The most obvious reason. Pottery involves chemicals, heat, and all sorts of things you don’t want in your eyes or lungs. - Quality of Work

Being safe lets you focus on your art without the nagging fear of getting hurt, so you’re free to dive into your work without holding back. - Long-Term Health

Pottery isn’t just about the here and now; you’ve got to think long-term. PPE is an investment in a long and healthy pottery career. - Legal Requirements

Depending on where you’re working, PPE might not just be recommended; it might be required. So unless you want to get hit with fines or shutdowns, gear up!

9 Maintenance and Calibration

It’s Like Taking Your Car to the Mechanic, But for Your Kiln

Maintenance and calibration, the unsung heroes of the pottery world. Just like you wouldn’t drive your car forever without an oil change, you shouldn’t operate your kiln without regular checks and adjustments. It’s all about making sure your kiln is running as smoothly and accurately as possible.

What’s on the Checklist?

- Element Checks

The heating elements in an electric kiln wear out over time. Regularly inspect them for any signs of damage or wear, and replace them as needed. - Thermocouples and Pyrometers

These are your kiln’s temperature sensors. They need to be calibrated regularly to ensure they’re reading temperatures correctly. - Seals and Gaskets

These help maintain the kiln’s internal atmosphere. Check for wear and tear, and replace them if they’re looking a bit worse for wear.

Why This Isn’t Optional

- Accuracy

If your kiln isn’t calibrated correctly, your temperature readings could be off, leading to botched projects and wasted materials. - Efficiency

A well-maintained kiln is an efficient kiln. You’ll use less energy, which is good for both the planet and your wallet. - Longevity

Regular maintenance extends the life of your kiln. It’s an investment, so you want it to last as long as possible. - Safety

Neglected maintenance could lead to malfunctions or even accidents. Better to catch issues early than to deal with the aftermath of a kiln mishap.

10 Safety Protocols

Why It’s Like Having a Game Plan for the Unexpected

Safety protocols, are your go-to plans for when things go south. Whether it’s a thermal burn, a gas leak, or some freaky electrical malfunction, having established guidelines can be a lifesaver—sometimes literally.

The Big Three – Burns, Leaks, and Malfunctions

- Thermal Burns

Know where your first-aid kit is and how to use it. Thermal burns should be cooled immediately with cold water, and severe burns require medical attention, ASAP. - Gas Leaks

If you smell gas or your carbon monoxide detector goes off, you need to evacuate and contact emergency services. Gas leaks are no joke. - Electrical Malfunctions

Sparks, sudden shutdowns, or any unusual behavior from your kiln could signify an electrical issue. Know how to safely shut down your kiln and when to call in a professional.

Why You Can’t Just Wing It

- Immediate Action

When something goes wrong, you don’t have time to Google “what to do if I burn myself.” You need to act fast, and that’s where protocols come in. - Minimizing Damage

Quick and correct action can mean the difference between a minor hiccup and a major catastrophe. Knowing what to do can minimize damage to both you and your equipment. - Legal and Insurance Reasons

Having clear safety protocols can be required for insurance purposes or to comply with local regulations. It’s not just smart; it could be obligatory. - Peace of Mind

Knowing you’re prepared allows you to work more freely and creatively. It’s like having a safety net; you hope you never need it, but it’s nice to know it’s there.

How Can The Cement Plant Operations Handbook Help With Advanced Kiln Operations?

Why Cement Plants and Pottery Aren’t Worlds Apart

At first glance, you might be thinking, “What does a cement plant have to do with my pottery studio?” Well, hear me out. The Cement Plant Operations Handbook is a treasure trove of information on kiln operations that can actually be super useful for anyone involved in firing ceramics, even though its primary audience is the cement industry.

The Transferable Wisdom

- Heat Management

Cement kilns and pottery kilns both deal with extreme heat. The handbook goes into intricate details about managing heat efficiently, which can be applied to pottery kilns as well. - Fuel Types and Combustion

It gives you the lowdown on different fuels, how they burn, and how to control combustion. Super helpful when you’re trying to understand flame characteristics in your own kiln. - Maintenance Tips

Those chapters on routine checks and upkeep? Gold. Keep your kiln in tip-top shape using advice that’s been honed in an industrial setting.

Why You Might Want to Give It a Read

- Broaden Your Knowledge

Understanding the science and engineering principles that also apply in industrial settings can deepen your understanding of your own smaller-scale operations. - Problem-Solving

If you hit a snag with your kiln, the handbook might offer a solution. It’s like having a kiln expert on call 24/7. - Safety Protocols

Industrial settings have rigorous safety standards, and some of that wisdom can be applied in your studio. Always good to learn from the pros, right?

What Are The Advantages Of Using A Precalciner Kiln System For Advanced Kilns?

Why It’s Like Having a Turbo-Charged Engine in Your Kiln

The term “precalciner kiln system” floating around and you’re wondering what the big deal is? Well, let me tell you, it’s kind of like adding a turbocharger to your car’s engine. In the pottery world, a precalciner system takes your kiln operations to a whole new level.

The Meat and Potatoes of a Precalciner System

- Efficiency in Fuel Use

Precalciner systems preheat the materials before they enter the kiln, meaning you need less fuel to reach the desired temperature. It’s like warming up your car in winter before a long drive. - Quality Control

The preheating process allows for more consistent heating throughout, which is a godsend when you’re aiming for uniform results. - Faster Firing Times

Because materials are preheated, the kiln reaches the target temperature more quickly. It’s like using a fast-pass at an amusement park—skip the line and get straight to the fun part.

Why You Might Want to Consider This Setup

- Cost Savings

Reduced fuel use equals reduced costs. Over time, this can add up to significant savings, making the initial investment worth it. - Environmental Benefits

Less fuel consumption means a smaller carbon footprint. So, you can create your art and be kinder to Mother Earth at the same time. - Adaptability

Precalciner systems can be adapted to work with various types of fuel. This gives you flexibility if you ever need to switch fuel types for any reason.

Are There Any Special Chemical Considerations When Working With Advanced Kilns?

Why It’s Not Just About Cranking Up the Heat

With advanced kilns, you might think it’s all about mastering temperatures and firing schedules. But wait, there’s more! Chemical considerations also come into play, and trust me, they’re not to be overlooked.

The Chemical Actors on the Kiln Stage

- Glaze Components

Advanced kilns often reach higher temperatures, which can change how glazes react. You might get different colors or textures than you’d expect, and some glazes might even become unstable. - Clay Body Reactions

At higher temperatures, the clay can undergo more complex chemical changes, affecting its strength, porosity, and even color. - Fuel Combustion Byproducts

If you’re using gas or wood, the combustion process can release chemicals that interact with your work. Ever heard of wood ash glazing? That’s a chemical reaction for you!

Why You Should Care

- Safety First

Some of the chemicals released during high-temperature firings can be hazardous. Proper ventilation and PPE become even more critical. - Quality of Work

If you’re not aware of how chemicals will behave at advanced kiln temps, you might end up with unexpected and unwelcome results. - Material Costs

Some materials react differently at higher temperatures, meaning you might need to invest in special clays or glazes that can handle the heat without going haywire. - Environmental Impact

The byproducts of certain chemical reactions can be harmful to the environment. Responsible disposal and emission control are key.

How Do The Principles Of Thermodynamics Apply To Controlling And Managing Energy Consumption In An Efficient And Safe Manner Within An Advanced Rotary Kiln Environment?

The Science Behind the Kiln, It’s Not Just Hot Air

Okay, stick with me here, because we’re about to go on a mini science journey. Thermodynamics isn’t just something you snoozed through in high school physics; it’s actually super relevant when you’re dealing with advanced rotary kilns. Understanding how energy is transferred and transformed can help you operate your kiln more efficiently and safely.

Thermodynamics 101 for Potters

- First Law, Energy Conservation

Energy can’t be created or destroyed, just converted. This principle helps you realize that optimizing your kiln’s energy usage isn’t just about cranking up the heat—it’s about how that heat is distributed and retained. - Second Law, Entropy

In simple terms, energy naturally wants to spread out. Knowing this helps you understand why insulation is crucial in kilns, to keep the heat where you want it. - Heat Transfer Mechanisms

Conduction, convection, and radiation are the key ways heat moves around in a kiln. Each has its role, and understanding them can help you tweak your firing processes for better results.

Why You Should Care

- Energy Efficiency

Using thermodynamic principles, you can optimize your kiln’s energy consumption, which is both eco-friendly and cost-effective. - Safety Measures

Understanding how heat moves can help you set up your kiln in a way that minimizes safety risks, like hotspots or uneven heating that can cause cracks or explosions. - Quality Control

Better control over your kiln’s internal environment means more consistent results, which is always a win in my book.

Frequently Asked Questions

Q: What are the main principles of thermodynamics in kilns?

A: The first law focuses on energy conservation, stating that energy can’t be created or destroyed, only converted. The second law deals with entropy, explaining that energy tends to disperse. Heat transfer mechanisms like conduction, convection, and radiation are also key.

Q: How can a precalciner system benefit my kiln operations?

A: A precalciner system preheats materials, reducing fuel use and costs. It also allows for more consistent and quicker heating, improving the quality and efficiency of your firing processes.

Q: What are some chemical considerations in advanced kilns?

A: Be mindful of how glazes and clay bodies react at higher temperatures. Fuel combustion byproducts can also interact with your work. Always maintain proper ventilation and use PPE to handle potential hazards.

Q: What’s the importance of maintenance and calibration?

A: Regular checks and adjustments ensure your kiln operates efficiently and accurately. It extends the lifespan of your kiln and helps you avoid malfunctions or safety issues.

Q: Can the Cement Plant Operations Handbook help with kilns?

A: Yes, although it’s geared towards the cement industry, the handbook provides valuable insights into heat management, fuel types, and maintenance that can be applied to pottery kilns.

Q: What are the three zones of the rotary kiln?

A: The three main zones are the drying or preheating zone, the calcining or burning zone, and the cooling zone. In the drying zone, moisture is removed from the material. In the calcining zone, the actual chemical changes occur, turning the raw material into clinker. The cooling zone cools the clinker for further processing.

Q: What is kiln operation?

A: Kiln operation refers to the process of managing and controlling a kiln to achieve desired firing outcomes. It involves regulating temperature, managing fuel types, controlling the internal atmosphere, and following safety protocols. The aim is to fire ceramic or other materials to a specific temperature profile while maintaining quality and safety.

Q: How does a Precalciner work?

A: A Precalciner is a secondary combustion chamber separate from the kiln. It is used to preheat raw materials before they enter the kiln, thus reducing the energy required to bring them up to temperature within the kiln itself. This leads to more efficient fuel use, quicker firing times, and more consistent results.

Q: What is the largest rotary kiln in the world?

A: The largest rotary kiln in the world was reported to be at the Qarachog Cement Plant in Iraq, with a length of 170 meters and a diameter of 7.8 meters. It’s used primarily for the production of cement. However, records can change, and it’s best to consult the latest industry reports for the most current information.

References

Footnotes

- https://www.paragonkilns.com/products/sentry-2-0-controller ↩︎