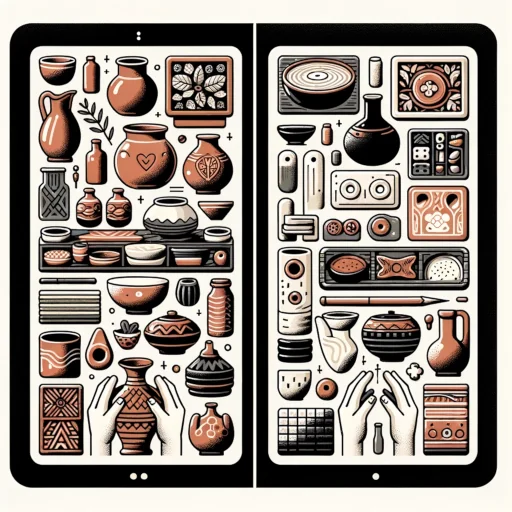

The terms Pottery and Ceramics are often used interchangeably, but they are not the same. The difference is Pottery is a form of ceramics, but not all ceramics are pottery. Pottery specifically refers to objects made from clay and then fired in a kiln. It’s generally more focused on utilitarian items like bowls, plates, and vases. Ceramics, on the other hand, is a broader category that includes pottery but also encompasses other items like tiles, porcelain, and even some industrial products. Ceramics can be made from various materials, including clay, but also porcelain and bone china. The key difference lies in the material used and the intended function of the finished product.

The Difference

While pottery and ceramics are closely related, they are not the same. Pottery is a form of ceramics focused on utilitarian objects made from clay. Ceramics is a broader field that includes pottery but extends to a wide range of materials and applications, from art to industry. Understanding these differences can help you appreciate the unique qualities and possibilities each offers.

Differences

Pottery

Pottery is a subset of ceramics that specifically deals with the creation of objects made from clay. These objects are then fired in a kiln to harden them. Pottery is generally more focused on utilitarian items like bowls, plates, and vases.

Ceramics

Ceramics is a broader term that encompasses pottery but also includes other items like tiles, porcelain, and even some industrial products. Ceramics can be made from various materials, including clay, porcelain, and bone china.

Material Used

Pottery

Pottery is almost exclusively made from clay, which can vary in composition but generally includes kaolinite.

Ceramics

Ceramics can be made from a wider range of materials, including earthenware, stoneware, porcelain, and advanced ceramics like alumina and silicon carbide.

Firing Temperature

Pottery

Pottery is generally fired at lower temperatures, ranging from 1,800 to 2,200 degrees Fahrenheit, depending on the type of clay used.

Ceramics

Ceramics, especially porcelain and bone china, are often fired at much higher temperatures, sometimes exceeding 2,600 degrees Fahrenheit.

Functionality vs. Aesthetics

Pottery

Pottery often leans more towards functionality. While it can be decorative, its primary purpose is usually utilitarian.

Ceramics

Ceramics can be both functional and decorative. Fine ceramics are often more about aesthetics and can be seen as art pieces.

Durability

Pottery

Pottery tends to be more porous and less durable compared to other ceramic products. It’s often not suitable for holding liquids for an extended period unless glazed.

Ceramics

Ceramics, especially those made from materials like porcelain, are much more durable and are often used in high-stress applications like industrial parts.

Deeper Dive: How does the nuanced difference between “pottery” and “ceramics” reflect broader societal attitudes toward craftsmanship, art, and utility, and what does this reveal about our cultural values and perceptions?

I’m sure you’ll agree the distinction between “pottery” and “ceramics” opens up a range of considerations that go beyond mere semantics.

My question invites an exploration of how the terms we use and the distinctions we make can serve as a lens through which we view not just objects, but broader concepts like utility, artistry, and even cultural value.

The nuanced difference between “pottery” and “ceramics” can tell us a lot about societal attitudes towards craftsmanship, art, and utility, as well as reveal underlying cultural values and perceptions. Here’s my explanation:

Craftsmanship

- Valuation of Skill: Pottery, often seen as a craft, may be valued for the skill and technique required to create functional items. In contrast, ceramics, which encompass a broader range of items, including art objects, might be valued more for innovation and artistic vision.

- Traditional vs. Modern: Pottery is often associated with traditional craftsmanship, while ceramics might be seen as encompassing more modern, industrial processes, reflecting varying societal attitudes towards tradition and modernity.

Art

- Artistic Merit: The term “ceramics” may carry a more artistic connotation, especially when it encompasses non-utilitarian objects. This can reflect a societal tendency to elevate “art for art’s sake” over functional craftsmanship.

- Medium vs. Message: In pottery, the medium (clay) often dictates the form and function of the object. In ceramics, the range of possible materials and functions allows for more focus on the artistic message, which may be independent of the medium.

Utility

- Function Over Form: Pottery, often focused on utilitarian objects like bowls and plates, reflects a societal value placed on function. Ceramics, with its broader scope, allows for objects that are purely decorative, highlighting a different set of values focused on aesthetics.

- Everyday vs. Special Occasion: Pottery items are often those we encounter in daily life (dishes, plant pots), while ceramic items might be those we associate with special occasions or artistic displays, reflecting different societal contexts for utility and luxury.

Cultural Values and Perceptions

- Accessibility: The perception of pottery as more “everyday” and ceramics as more “elevated” or “artistic” can reflect cultural attitudes about accessibility and elitism in art and craftsmanship.

- Heritage and Identity: Pottery, often linked to specific cultural traditions and historical practices, can carry a weight of cultural identity. Ceramics, being broader, might be seen as more cosmopolitan or universal, reflecting different facets of cultural value.

- Economic Implications: The different societal values attached to pottery and ceramics can also have economic ramifications, affecting the pricing, market demand, and even the investment in educational and developmental resources for these crafts.

I say, the terms “pottery” and “ceramics” serve not just to categorize different types of objects but also to illuminate broader societal attitudes and cultural values. They become a lens through which we can explore how society views the interplay of function, art, craftsmanship, and culture.

Origins of Pottery and Ceramics

Both pottery and ceramics have rich histories that have evolved over thousands of years. While they originated as distinct practices, today they often intersect, each enriching the other with techniques, materials, and artistic possibilities.

The Dawn of Pottery

Pottery is one of the oldest human inventions, dating back to the Neolithic period around 10,000 to 12,000 years ago. Early potters used locally sourced clay and simple tools to shape utilitarian objects like bowls, jars, and cooking pots. These objects were then fired in rudimentary kilns, often just pits filled with wood or dried manure. The primary purpose of these early pottery pieces was functional, serving as containers for food, water, and other essentials.

Neolithic Innovations

During the Neolithic period, pottery became more sophisticated with the introduction of the potter’s wheel, which allowed for more uniform and intricate shapes. Decorative elements like engravings and natural ash glazes started to appear, indicating a shift towards aesthetic considerations.

The Birth of Ceramics

While pottery focused on utilitarian objects, ceramics as a broader category began to take shape much later. The term “ceramics” comes from the Greek word “keramos,” meaning “potter’s clay,” but it has evolved to include a wide range of materials and techniques.

Porcelain and Bone China

One significant milestone in the evolution of ceramics was the invention of porcelain in China around the 7th century. Unlike traditional pottery clay, porcelain offered a translucent quality and higher durability. Bone china, a type of porcelain containing bone ash, was later developed in Europe and became highly prized for its delicate appearance and strength.

The Intersection of Pottery and Ceramics

Over time, the lines between pottery and ceramics have blurred. Modern potters often incorporate ceramic techniques into their work, using materials like porcelain and stoneware. Similarly, ceramic artists may use traditional pottery methods to create non-utilitarian art pieces.

Uses for Pottery and Ceramics

Both pottery and ceramics offer a wide range of uses, from functional to decorative. While pottery tends to lean more towards utilitarian objects like cooking vessels, ceramics offer a broader range of applications, including fine art pieces. Regardless of your needs, both materials offer unique benefits that make them invaluable in everyday life and artistic expression.

Cooking Vessels

Pottery

Pottery has been used for cooking vessels for millennia. Earthenware pots and stoneware casseroles are popular for slow-cooking and baking. They’re known for their heat retention and even cooking, making them ideal for stews, soups, and casseroles.

Ceramics

Ceramic cookware, often made from porcelain or specialized ceramic blends, is also widely used. These are usually coated with a glaze that makes them non-stick and easy to clean. They’re great for baking dishes, pie plates, and even ceramic stovetop cookers.

Vases

Pottery

Pottery vases often have a rustic, earthy quality that makes them perfect for a wide range of floral arrangements. They’re generally heavier and more robust, making them ideal for larger, taller flowers.

Ceramics

Ceramic vases, especially those made from fine materials like porcelain, offer a more refined look. They’re often intricately designed and may feature detailed paintings or patterns. These are usually more delicate and are better suited for more formal settings.

Bowls

Pottery

Pottery bowls are a staple in many households. They’re perfect for serving soups, salads, and even for mixing ingredients. The porous nature of unglazed pottery can also help keep bread and other baked goods fresh by absorbing excess moisture.

Ceramics

Ceramic bowls come in a variety of shapes and sizes, often with intricate designs and glazes. They’re generally smoother and may have a more uniform appearance than their pottery counterparts. These are versatile and can be used for anything from serving to decorative purposes.

Firing Methods for Pottery and Ceramics

Whether you’re working with pottery or ceramics, the firing method you choose can significantly impact the final product. From bisque and glaze firings to more specialized techniques like Raku and salt firing, each method offers its own set of challenges and rewards. Understanding these methods can help you make informed decisions in your pottery or ceramic projects.

Bisque Firing

Pottery

In pottery, bisque firing is the first firing and is usually done at a lower temperature. This process hardens the clay, making it easier to handle and less porous.

Ceramics

In ceramics, bisque firing serves the same purpose. It prepares the ceramic piece for glazing by removing all the physical water and most of the chemical water from the clay.

Glaze Firing

Pottery

Glaze firing in pottery is typically done at higher temperatures and is where the glaze materials melt to form a glass-like surface. This is what gives pottery its waterproof quality and aesthetic finish.

Ceramics

In ceramics, especially fine ceramics like porcelain, glaze firing can be a highly controlled process, often involving multiple firings to achieve intricate designs and finishes.

Raku Firing

Pottery

Raku is a firing process that originated in Japan and is often used in pottery. The pieces are removed from the kiln while still hot and placed into containers with combustible materials, creating unique patterns and colors.

Ceramics

Raku can also be used in ceramics for creating decorative pieces. However, it’s less common in functional ceramics due to the porous nature of the end product.

Salt and Soda Firing

Pottery

In pottery, salt and soda firing are methods where salt or soda is introduced into the kiln at high temperatures. This creates a sodium vapor that reacts with the clay, forming a unique glaze.

Ceramics

In ceramics, these methods are less commonly used but can be found in specialized artistic applications.

Wood Firing

Pottery

Wood firing is an ancient method where wood is used as fuel. The ash from the wood can create natural glazes, and the flame path can create unique patterns.

Ceramics

In ceramics, wood firing is generally reserved for specific artistic projects due to the unpredictability of the results.

The Impact of Silica Carbide on Pottery and Ceramics

Silicon carbide plays a unique role in both pottery and ceramics. In pottery, it’s valued for its durability in kiln shelves and its ability to create special glaze effects. In ceramics, it’s used in advanced applications that require a material that can withstand extreme conditions. Its versatility and durability make it a valuable material in both fields.

Introduction to Silica Carbide

Silicon carbide (often abbreviated as SiC) is a synthetic material known for its hardness and its ability to withstand high temperatures. It’s commonly used in industrial settings but has also found its way into the world of pottery and ceramics.

Pottery

Kiln Shelves

In pottery, silicon carbide is often used in kiln shelves. These shelves are exposed to extreme temperatures, and silicon carbide’s high thermal stability makes it an ideal material for this application.

Glaze Effects

Some potters use silicon carbide to create special glaze effects. When added to glazes, silicon carbide can produce bubbles and a metallic sheen, adding complexity and texture to the finished piece.

Ceramics

Advanced Ceramics

In the field of advanced ceramics, silicon carbide is a key material. It’s used in a variety of high-performance applications, including cutting tools, bearings, and armor plates. Its hardness and thermal stability make it ideal for these uses.

Kiln Furniture

Just like in pottery, silicon carbide is used in kiln furniture in ceramics. It can withstand the high temperatures of ceramic firing cycles and is less likely to deform or break compared to other materials.

Electrical Components

Silicon carbide is also used in ceramic electrical components like LEDs and even in semiconductor devices. Its electrical conductivity can be manipulated through a process called doping, making it useful in a variety of electronic applications.

The Process of Turning Dried Clay into Pottery or Ceramic

Turning a dried clay object into a piece of pottery or ceramic is a multi-step process that involves careful preparation, shaping, drying, firing, and glazing. Each step is crucial to achieving a finished product that is both beautiful and functional.

Preparing the Clay

Wedging

The first step in the process is to prepare the clay. This often involves “wedging,” which is a kneading technique that removes air bubbles and ensures a uniform consistency.

Shaping

Once the clay is prepared, it’s shaped into the desired form. This can be done by hand, using a potter’s wheel, or through molds.

Drying the Object

Air Drying

After shaping, the clay object must be dried. This is usually done at room temperature and can take several days. The goal is to remove most of the moisture content.

Leather-Hard Stage

The object is often allowed to reach a “leather-hard” stage where it is firm but still damp. This makes it easier to carve or add details.

First Firing: Bisque Firing

Kiln Preparation

The dried object is then placed in a kiln for its first firing, known as bisque firing. The kiln is gradually heated to remove any remaining moisture.

Temperature

The temperature for bisque firing is usually lower than for glaze firing, often between 1,700 to 1,900 degrees Fahrenheit.

Glazing

Applying the Glaze

After bisque firing, the object is ready for glazing. The glaze can be applied in various ways, including dipping, brushing, or spraying.

Drying the Glaze

Once applied, the glaze needs to dry before the object can be fired again.

Second Firing: Glaze Firing

Kiln Preparation

The object is returned to the kiln for its second firing, known as glaze firing. This is where the glaze melts and forms a glass-like surface.

Temperature

The temperature for glaze firing is higher than for bisque firing, often exceeding 2,200 degrees Fahrenheit.

Cooling and Inspection

Cooling

After glaze firing, the object needs to cool down slowly to room temperature. This can take several hours or even days, depending on the size of the object and the kiln.

Inspection

Once cooled, the object is inspected for any cracks, bubbles, or imperfections in the glaze. If it passes inspection, it’s now a finished piece of pottery or ceramic.

Types of Production Pottery: Stoneware vs Porcelain

Both stoneware and porcelain offer unique advantages and disadvantages. Stoneware is durable and versatile, making it ideal for everyday use. Porcelain, on the other hand, is prized for its beauty and refinement but is generally less robust than stoneware. Understanding these differences can help you choose the right type of production pottery for your needs.

Introduction

When it comes to production pottery, there are various types of clay bodies used to create different kinds of pottery. Two of the most common types are stoneware and porcelain. Each has its own unique characteristics, advantages, and disadvantages.

Stoneware

Definition and Characteristics

Stoneware is a type of pottery that is fired at high temperatures, usually between 2,100 and 2,400 degrees Fahrenheit. It is known for its durability and strength, making it ideal for functional pieces like dinnerware and bakeware.

Color and Texture

Stoneware usually has a more earthy, natural color, ranging from grey to brown. The texture can be smooth or slightly rough, depending on the finishing techniques used.

Glazing

Stoneware is often glazed to make it waterproof, but it can also be left unglazed for a more rustic appearance. The glazes used can vary widely in color and texture.

Uses

Stoneware is commonly used for everyday items like mugs, bowls, and plates. It’s also popular for bakeware due to its ability to withstand high temperatures.

Porcelain

Definition and Characteristics

Porcelain is a type of ceramic pottery that is fired at even higher temperatures, often exceeding 2,600 degrees Fahrenheit. It is known for its fine texture, translucency, and pure white color.

Color and Texture

Porcelain is usually white and has a smooth, glass-like texture. It’s often translucent when held up to light, which is a hallmark of its purity and quality.

Glazing

Porcelain pieces are usually glazed to enhance their smooth texture and to add decorative elements. The glazes can range from simple, transparent finishes to intricate, multi-colored designs.

Uses

Porcelain is often used for fine china, decorative pieces, and art objects. It’s less commonly used for everyday items due to its fragility compared to stoneware.

FAQ: What is The Difference Between Pottery And Ceramics

Understanding the differences between pottery and ceramics, as well as their respective histories, types, and uses, can provide a deeper appreciation for these ancient yet continually evolving art forms.

Historical Context

Q: When was the word ceramics first used to describe objects made from clay?

A: The term “ceramics” comes from the Greek word “keramikos,” meaning “of pottery.” It has been used for centuries but became more widespread with the advent of industrial ceramics in the 19th and 20th centuries.

Types of Kilns

Q: What are the 3 main types of kilns?

A: The three main types of kilns are electric kilns, gas kilns, and wood-fired kilns.

Q: What is a kiln that is loaded from the top called?

A: A kiln that is loaded from the top is commonly referred to as a “top-loading kiln.”

Q: What is the difference between an electric kiln and a gas kiln?

A: Electric kilns are easier to control in terms of temperature but may be more expensive to operate. Gas kilns offer a more traditional firing process and can produce unique textures and colors.

Q: What are the different types of modern kilns?

A: Modern kilns include tunnel kilns, rotary kilns, and car kilns, among others.

Material Characteristics

Q: How can translucent white ceramic be made in contrast to opaque pieces of pottery?

A: Translucent white ceramic, often porcelain, is fired at higher temperatures and is made from purer forms of clay, usually kaolin, which allows for its translucent quality.

Q: Is fine white clay more difficult to work with than other types of clay when making pottery and ceramic artwork?

A: Fine white clay, like porcelain, is generally more difficult to work with due to its sensitivity to moisture and its tendency to crack during drying and firing.

Usage and Design

Q: What are some popular uses for Porcelain dishes today compared to centuries ago?

A: Today, porcelain dishes are commonly used for fine dining and decorative pieces. Centuries ago, they were often reserved for royalty and the elite.

Q: How has the design of pottery and ceramic changed over time since its invention centuries ago?

A: The design has evolved from simple, functional pieces to intricate works of art, thanks in part to advancements in technology and materials.

Storage and Preservation

Q: Do storage jars need to be glazed differently than other forms of pottery or ceramics in order to retain their contents better over time?

A: Storage jars often require a more durable glaze to ensure they are waterproof and airtight, which helps to preserve their contents over time.