It’s, often referred to as a “bat,” its’ a portable, removable platform that attaches right onto the wheel head of your pottery wheel. They’re typically made from plastic, composite materials, or plaster, and come in various sizes to suit the different projects you might be working on.

Bats are incredibly useful for a number of reasons.

- The primary one is that a pottery bat allows you to remove your pot from the wheel without touching the pot itself, which is particularly useful when your piece is still wet and easily distorted. Just imagine trying to carefully lift a freshly thrown, intricate bowl directly off the wheel – it’s nearly impossible to do without altering the shape or leaving fingerprints!

- Also, pottery bats give you the flexibility to work on multiple pieces in a session without needing multiple wheels. You can simply remove the bat with the attached pot, set it aside to dry, and attach a new bat to the wheel to start your next piece.

They’re one of those tools that once you start using, you wonder how you ever did without. Trust me, the bat has saved many a pot from a premature end in my garage studio!

What Are The Different Types Of Pottery That Can Be Created?

Oh, the possibilities are endless when it comes to what you can create with a pottery wheel bat! It’s one of the reasons I fell in love with pottery all those years ago. The sheer variety of forms you can create is only limited by your imagination and skill level. But let’s dive into a few examples.

- Firstly, bowls are probably one of the most common things created on a pottery wheel. They’re a perfect project for beginners as well as seasoned potters. You start by centering your clay on the bat, and then you open up the middle and pull the walls to create the desired depth and width. I personally love the challenge of trying to make a set of bowls that match perfectly – it’s harder than it sounds!

- Vases, on the other hand, can be a bit more challenging because of their typically narrower necks and wider bodies. It’s an exercise in control and precision, and no two vases ever come out exactly the same. It’s always an exciting moment when you remove a newly thrown vase from the bat, just to see how this one turned out.

The System

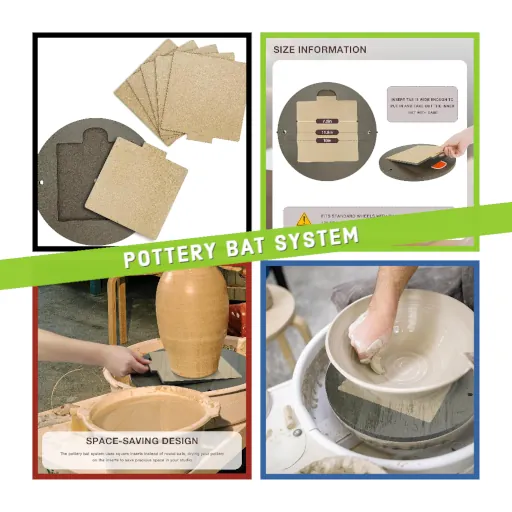

It’s one of those tools in pottery that can really take your craft to the next level. A pottery bat system is a set of wheel bats that are interchangeable on a single bat pin holder, allowing you to throw multiple pieces without removing the clay from the bat. It’s a fantastic time and effort saver, especially for larger or more intricate pieces that you don’t want to handle too much before they’ve had a chance to firm up.

The system typically includes a main bat with holes or slots in it that align with the bat pins on your wheel head. This main bat stays on the wheel, while the individual bats, which you throw your pots on, can be swapped in and out. These individual bats are designed to snugly fit into the main bat, ensuring a stable and secure workspace while you throw.

Go to Shop Artabys: Pottery Bat System

The pottery bat system leverages square inserts in lieu of traditional round bats, enabling your pottery to dry on these inserts, thus saving significant space and invaluable time. This system is compatible with standard pottery wheels, designed to fit those with pin holes that are 10″ apart at the center. Built from waterproof and long-lasting Compact Laminate material, these bats ward off water absorption and shield your pots from any potential harm and distortion.

I believe the real advantage of a bat system comes in when you’re working on multiple pieces in a day or producing a series of similar pieces. You can simply swap out the bat with the freshly thrown pot and start on a new piece right away. Plus, it minimizes the risk of distorting your pot when you need to move it off the wheel.

The bat system also allows pots with wide bottoms or delicate forms to be removed without distortion or damage, as the pot can be left on the bat to dry until it’s leather-hard and easier to handle. Using a bat system can really made a difference in terms of the efficiency of work and the integrity of the pieces you create.

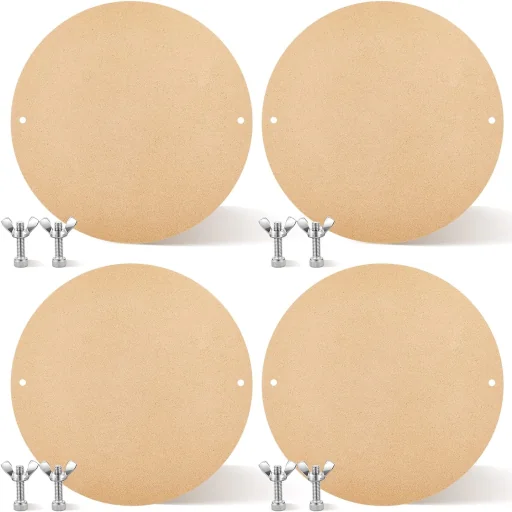

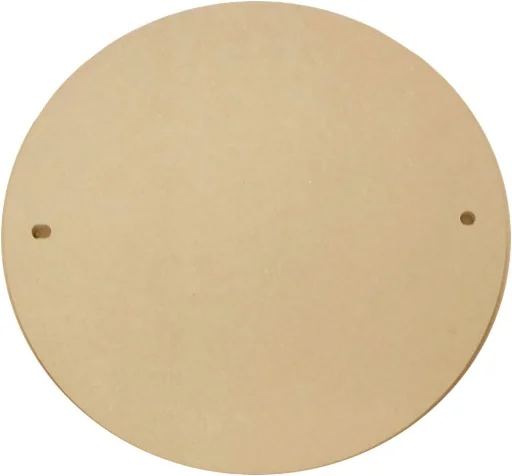

Pottery Wheel Bat With Pins

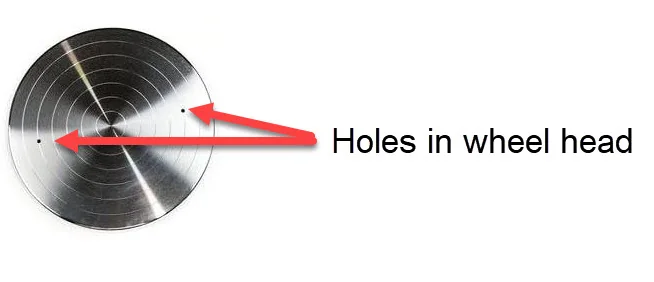

Wheel bats with pins. They’re a staple in many pottery studios. These types of bats have small holes drilled into them that align with pins set into the wheel head. When you’re ready to start throwing, you simply align the holes in the bat with the pins on the wheel, and the bat will stay put while you work.

Pottery Wheel Bats With Pins Advantages

There are several advantages to using wheel bats with pins. One of the main ones is that they can be easily swapped out, allowing you to start on a new piece without having to remove the still-wet clay from the bat. It’s especially useful if you’re making a lot of similar pieces – you can leave each piece on its bat to dry a bit while you start on the next one.

Another advantage is that bats with pins allow you to move your work with less risk of warping or damaging the piece. Instead of trying to slide a wire under the piece or lift it off the wheel head, you can simply lift the entire bat off the wheel and set it aside.

Pottery Wheel Bats With Pins Disadvantages

Of course, like any tool, bats with pins have a few downsides as well. They do require an investment up front, and while they’re not prohibitively expensive, it can add up if you need to buy a lot of them. They can also sometimes be a bit tricky to align perfectly, especially if your hands are already full of clay! Plus, you do need to keep track of them and store them properly when not in use to avoid warping or other damage.

In my experience, however, the benefits of using bats with pins far outweigh the costs. I’ve found that they increase efficiency, reduce the risk of damaging pieces, and overall make the throwing process smoother and more enjoyable.

Pottery Bat Materials

Go to Shop Artabys: Speedball Universal Pottery Wheel Bats for Ceramics and Clay Work

The “Easy Lift Rim” enables seamless removal of the bat from the wheel head, ensuring the pot remains unaffected. These bats, constructed from injection-molded plastic, are designed for longevity, with special ribs contributing to their robustness and endurance. They are tailored to align with any wheel bat pin spacing.

Over the years, I’ve experimented with a variety of pottery bat materials. Each comes with its own set of benefits and potential drawbacks. Here’s my quick run-down:

| Pottery Bat Material | Description | Advantages | Disadvantages |

|---|---|---|---|

| Wood | Traditional bats made from particle board, MDF, or plywood. | – Reasonably priced – Good balance of durability and affordability | – Can warp over time – Absorbs water |

| Plastic | Water-resistant and easy-to-clean bats. | – Doesn’t warp – Reliable and durable | – Slippery when wet – More expensive than wooden bats |

| Plaster | Bats that can absorb excess moisture from clay. | – Helps pots release easily due to moisture absorption | – Heavy and fragile – Can break easily |

| Masonite | A type of engineered wood that has a smooth, hard surface. | – Resists warping – Less absorbent than regular wood | – Can wear out over time |

| Composite Materials (Medex or Masonite) | Bats made from materials like Medex or Masonite, designed to resist water. | – Resistant to water – Good long-term investment | – Typically more expensive |

| Canvas or Cloth | Used mainly for hand-building or sculpting, but not for throwing on a wheel. | – Lightweight – Portable | – Not suitable for wheel use |

This table gives a snapshot of the main materials used for pottery bats, outlining their general descriptions, advantages, and disadvantages.

Wood Pottery Bats

Many traditional bats are made from particle board, MDF, or plywood. They’re reasonably priced and offer a good balance of durability and affordability. However, they’re not as long-lasting as some other materials, and they can warp over time if they’re not dried and stored correctly. Also, wooden bats tend to absorb water, which can make it a bit trickier to get your pot off the bat once it’s thrown.

Plastic Pottery Bats

Plastic bats are water-resistant and easy to clean. They don’t warp, making them a reliable choice for many potters. On the downside, they can be a bit more slippery when wet compared to wooden bats, so you might have to take extra care when centering your clay. They also tend to be more expensive than wooden bats.

Is there any downside to using plastic versus hardboard bats when throwing on the wheel heads?

Ah, the debate between plastic and hardboard bats, a topic that’s seen many a pottery studio conversation! Both have their own advantages and potential downsides, and the choice often comes down to personal preference and the specific project you’re working on.

Now, starting with plastic bats, these guys are usually more durable than hardboard bats and don’t warp over time. They’re incredibly easy to clean, and clay tends to stick to them quite well, which is useful when you’re throwing. The major downside? They’re usually a bit more expensive than hardboard bats.

Hardboard bats, on the other hand, are generally less costly and lighter than their plastic counterparts, making them a bit easier to handle, especially for beginners. Clay also adheres well to them, perhaps even better than to plastic. But, they do have their disadvantages. They can warp over time if not cared for properly, which can be a real frustration when you’re in the middle of a project. Also, they’re porous, so they can become stained and are a bit harder to clean than plastic bats.

In the end, the choice between plastic and hardboard bats often comes down to personal preference, your budget, and the type of pottery you’re creating. It’s also not uncommon to find both types in a potter’s collection, as they each have their unique strengths.

Plaster Pottery Bats

Plaster bats are great for absorbing excess moisture from the clay, which can help pots release more easily. However, they’re heavier and more fragile than other options, and they can break if dropped.

Plaster bats are an interesting option and they do have some unique attributes.

Plaster Pottery Bat Advantages

Firstly, plaster bats are fantastic when it comes to absorbing water, and this is perhaps their most distinguishing feature. This property of plaster bats is incredibly useful when throwing clay because it helps to quickly and evenly remove excess water from the bottom of the clay, which is often a challenge with other bat materials. It can also help in reducing the risk of your piece cracking or warping as it dries.

Another thing I’ve noticed in my experience is that clay sticks pretty well to plaster bats without the need for any slip, so that can save you a bit of time and effort.

Plaster Pottery Bat Disadvantages

But, just like every material, plaster bats do have some downsides. Firstly, plaster bats can be a bit fragile compared to their wooden or plastic counterparts. They can chip or break if you’re not careful when handling or storing them.

Secondly, they require a bit more maintenance than other bat materials. After use, you need to let them dry thoroughly before the next use to prevent any potential damage. And over time, the plaster can wear down and require sealing or even replacing.

Finally, they tend to be a bit heavier than other bats, which can make them a bit more cumbersome to handle, especially for beginners or those who have physical limitations.

In summary, I think plaster bats can be a wonderful tool for some potters, particularly for those who throw larger pieces that need a lot of water absorption. But their fragility and the care they require may be a deterrent for others.

Masonite Pottery Bats

Masonite bats are a type of engineered wood, like particle board. They have a smooth, hard surface that resists warping, and they’re generally less absorbent than regular wood. They can wear out over time, though, and might not be as durable as plastic or composite bats.

Composite Pottery Bats

Composite bats, such as those made from Medex or Masonite and or similar materials, are designed to resist water, making them a good long-term investment. They’re typically more expensive, though.

Ceramic Pottery Bats

They are indeed an interesting option. They’re not as commonly used as wood, plastic, or composite bats, but they do have some unique features that can make them a good choice in certain situations.

Advantage of Ceramic Bats

The primary advantage of ceramic bats is their weight. They’re quite heavy, which can be a good thing when you’re throwing larger pieces. The weight of the bat can help keep the wheel stable, reducing the chance of wobbling or spinning off center.

Another advantage of ceramic bats is their durability. Ceramic is resistant to water damage, so unlike wood, ceramic bats won’t warp or crack over time. They’re also resistant to scratching, chipping, and other types of wear and tear. This can make them a good investment if you throw a lot of pots and need a bat that will stand up to heavy use.

Downsides to Ceramic Bats

On the other hand, there are also some downsides to using ceramic bats. The most obvious one is their cost. Ceramic bats tend to be quite a bit more expensive than other types of bats, which can be a barrier for some people. They’re also heavier, which can make them more difficult to handle, especially for beginners or those with physical limitations.

Another potential disadvantage is that ceramic bats can be more difficult to attach and remove from the wheel head than other types of bats. This is because ceramic is more slippery than materials like wood or plastic, so you may need to use bat pins or a similar attachment system to keep the bat in place.

In my personal experience, ceramic bats can be a great tool for certain types of projects, but they may not be the best choice for everyone. It all comes down to your individual needs, preferences, and budget.

Canvas or Cloth Pottery Bats Secrets

Some potters use a cloth or canvas bat for hand-building or sculpting, rather than throwing. It’s lightweight and portable, but not suitable for use on a wheel.

Each of these materials has its place in a potter’s studio, and the best one for you really depends on your personal preferences, your working style, and your budget. Personally, I recommend using a mix of different materials depending on what you working on.

Question: What is Your Preferred Pottery Bat Material?

How to Care for Pottery Bats | How to Clean Pottery Bats

Taking proper care of your pottery wheel bats can greatly extend their lifespan, and it’s an essential part of the craft. Here are my top tips for maintaining and storing your bats:

- Cleaning: After each use, it’s crucial to clean your bats. Use a metal rib or a plastic scraper to remove any remaining clay from the surface of the bat. Be gentle, you don’t want to scratch the surface. For any stubborn clay, you can use a damp sponge to wipe it clean. If you’ve been using a plaster bat, let it dry thoroughly before using it again to prevent damage.

- Drying: For bats made of wood, plaster, or any other absorbent material, it’s important to let them dry completely before storing them. This will prevent any mold growth or warping of the material. When drying your bats, lay them flat and flip them occasionally to ensure they dry evenly.

- Storage: When it comes to storing your bats, keeping them flat is key. If they’re stored leaning against a wall or stacked unevenly, they could warp over time. You can stack them neatly in a dry, temperate place. Extreme temperature or humidity changes can cause warping or other damage, particularly in wooden and plaster bats.

- Periodic Checks: Every now and then, check your bats for any signs of wear and tear. If you see any cracks, warping, or other damage, it’s best to replace the bat. Continuing to use a damaged bat could affect the quality of your pottery.

- Sealing: For wooden bats, consider sealing them with a waterproof varnish. This can help to prevent water absorption, which can lead to swelling and warping over time. Just make sure to use a food-safe varnish if you plan on making any tableware.

Should You Seal Wooden Bats?

The age-old debate in the pottery world: to seal or not to seal wooden bats. Let me break down the pros and cons for you.

Pros of Sealing Wooden Bats

- Durability: Sealing your wooden bats with a waterproof varnish can significantly increase their lifespan. It can prevent water absorption, which can lead to warping, swelling, and cracking over time.

- Ease of Cleaning: Sealed bats are easier to clean. The varnish prevents the clay from sticking to the surface, making it much simpler to scrape off.

- Smooth Surface: A good varnish leaves a nice, smooth surface which some potters prefer, as it allows for a smoother glide when forming your pieces.

Cons of Sealing Wooden Bats

- Loss of Absorbency: The most notable drawback of sealing wooden bats is that it reduces their absorbency. Some potters, like you mentioned, prefer their bats to be slightly absorbent, as it helps to pull excess moisture from the bottom of the pot, which aids in the drying process and can prevent cracking.

- Slipping: Depending on the type of varnish used, a sealed bat might become slippery when wet. This can make it difficult to keep the clay in place when throwing.

- Cost and Time: Sealing bats involves an additional expense for the varnish and takes extra time for the application and drying process.

Marine plywood is indeed a good choice for unsealed bats, as it’s designed to withstand a certain degree of moisture. However, it’s not entirely immune to the effects of constant wet-dry cycles over a prolonged period.

I have found there is no right or wrong answer as the decision to seal or not comes down to personal preference and the specific conditions in your studio. I say some potters find that unsealed bats work perfectly for their needs, while others prefer the durability and ease of cleaning that comes with a sealed bat. My experience has shown as with many things in pottery, it often involves a bit of trial and error to find what works best for you!

Maintenance Tips for Your Pottery Bat

Proper maintenance of your pottery bat is essential for its longevity and performance. While other articles may not delve into this topic, we believe it’s crucial for every potter to know how to take care of their equipment. Here are some maintenance tips for different types of pottery bat materials:

Masonite Bats

- Cleaning: Use a damp cloth to wipe off any clay residue.

- Storage: Store in a dry place to prevent warping and mold.

Plastic Bats

- Cleaning: Rinse with warm water and mild detergent.

- Storage: Stack neatly to avoid scratches.

Wood Bats

- Cleaning: Avoid soaking in water to prevent warping. Wipe clean with a damp cloth.

- Storage: Store flat and in a dry area.

Plaster Bats

- Cleaning: Scrape off dried clay with a plastic scraper.

- Storage: Keep in a cool, dry place.

Composite Bats (Medex or Masonite)

- Cleaning: Use a sponge or cloth with mild detergent.

- Storage: Store away from direct sunlight.

General Tips

- Regular Inspection: Check for cracks or warping before each use.

- Rotation: Rotate your bats regularly to ensure even wear.

- Disinfection: Occasionally disinfect your bats, especially if shared in a community studio.

By following these maintenance tips, you can extend the life of your pottery bat and ensure a smooth pottery-making process.

What is the difference between Round Plastic Pottery Wheel Bats and Speedball Plastic Bats?

The difference between Round Plastic Pottery Wheel Bats and Speedball Plastic Bats primarily lies in the brand and quality of the materials used.

Round Plastic Pottery Wheel Bats are a general term for bats made of plastic and can be from a variety of manufacturers. The quality and durability of these bats can vary greatly depending on the brand and type of plastic used.

On the other hand, Speedball is a well-known brand in the pottery world, renowned for their high-quality pottery tools and materials. Speedball Plastic Bats are part of their product line and are designed to be both durable and easy to clean. They are generally made from a high-density plastic that resists warping, cracking, and wear over time.

In terms of functionality, both types of bats do the same job. They provide a portable surface on which to work your clay on the wheel. The choice between the two would primarily come down to preference, budget, and the specific needs of your practice.

For instance, if you’re a beginner and you’re not sure how much you’ll use your bat, a generic round plastic bat might be a good and cost-effective starting point. If you’re a more serious potter or a professional, you might prefer investing in a Speedball Plastic Bat due to its long-lasting durability and reputation for quality.

Remember, the most important thing I say is to find a bat that suits your individual needs, feels comfortable to work with, and fits your budget.

The secret to adjusting bat pin spacing when using a Round Plastic Bat

Adjusting bat pin spacing for a round plastic bat or any bat, for that matter, largely depends on the wheel head you’re using. The wheel head is where the bat pins are inserted. Here’s a general guideline:

- You’ll first need to find the holes on the wheel head where the bat pins are to be inserted. These holes are usually evenly spaced around the wheel head’s center.

- Measure the distance between these holes (bat pin holes) on your wheel head. This distance varies from brand to brand but is typically either 10 inches or about 25.4 cm (common in many American brands) or 9 inches or about 22.9 cm (common in many European brands).

- Once you’ve measured the distance, find the corresponding holes on your plastic bat. Most plastic bats have multiple sets of holes to accommodate different pin spacings.

- Now, align the bat’s holes with the bat pin holes on your wheel head, and secure the bat onto the wheel head. Make sure the bat is properly centered and secured before you start throwing.

It’s worth mentioning that adjusting bat pin spacing can be a little tricky, especially if you’re new to pottery. But don’t worry, with a bit of practice, it becomes a breeze.

What is the OUTPOST POTTERY Tile Spinner and what advantages does it offer?

I believe the OUTPOST POTTERY Tile Spinner, is quite an innovative tool in our pottery world. It’s a unique piece of equipment designed for the easy creation and decorating of flat items like tiles and slabs.

One of the most prominent advantages of the Tile Spinner is that it makes creating tiles or slabs a breeze. It rotates just like a pottery wheel, allowing you to work on all sides of your flat piece without having to pick it up and risk distorting its shape. This saves time and can also increase the quality of your finished piece by keeping it more uniform throughout the decorating process.

Another significant benefit is its versatility. You can use it not only for making and decorating tiles but also for creating flat items like coasters or slabs for bigger hand-building projects. It’s particularly great for slip trailing, sgraffito, and other decorative techniques that benefit from a spinning platform.

Plus, it’s designed to hold tiles securely in place while you work, thanks to its non-slip surface. And it’s fairly lightweight and portable, so it doesn’t require a big dedicated space in your studio.

One thing to remember is that the Tile Spinner isn’t a replacement for a wheel or slab roller, but rather it’s an additional tool that can enhance your pottery making, especially if you’re into making tiles or working on flat pieces. It’s like a little helper that can make the decorating process a lot smoother. And for some, it’s a game-changer!

Can the Universal Bat System be used with any pottery wheel?

The beauty of the Universal Bat System, or UBS as we often call it, is in its name – it’s “universal.” This system is designed to fit the majority of pottery wheels out there, thanks to its flexible nature.

The central idea is that the UBS uses inserts, which are smaller square or round bats, that fit into a larger, more stable bat attached to the wheel head. These inserts can be easily removed and replaced, making it a snap to switch out pots without removing the entire bat.

The master bat, the large piece that attaches to the wheel head, has slots designed to accommodate the pins of the wheel head. These slots are generous in size, allowing the master bat to adjust to varying pin distances found on different wheels. So yes, this system can indeed be used with most pottery wheels.

However, while it’s designed with universality in mind, it’s always a good idea to double-check the specifics of your wheel and the Universal Bat System you’re considering. Some really unique or vintage wheel models may not perfectly align with the UBS. If you’re unsure, reach out to the manufacturer or distributor of the UBS to confirm its compatibility with your wheel. It’s always better to be sure before you invest.

How are Sanyour Signature Bats different from other pottery bats?

Sanyour Signature Bats! They hold a special place in many potters’ hearts, including mine. These bats are quite unique compared to most others on the market.

The major difference lies in the material used. Sanyour Signature Bats are made from a high-density polyethylene plastic, which is not only durable but also incredibly resistant to water and warping. That’s a huge advantage for us potters because we’re constantly dealing with moisture.

Unlike other bats, Sanyour Bats are also one piece, meaning there are no inserts. This provides a very sturdy and stable surface for throwing. The solidity of the bat makes it excellent for heavier pieces. Also, due to the plastic used, they are much lighter than many other types of bats, which can make handling them easier, especially when dealing with larger pieces.

They also feature double-sided use, with one side flat and the other slightly domed. The domed side is perfect for creating platters or plates, as it naturally gives a gentle lift to the edges of your pieces.

On the downside, they can be a bit pricier than other bats, but many potters feel the investment is well worth it for the longevity and versatility of these bats. They’re a real workhorse in the studio.

Are hardboard bats more durable than plastic ones, and why or why not?

That’s a great question! The durability of bats really depends on the material, how often they’re used, and how well they’re maintained. Hardboard and plastic bats each have their own strengths and potential issues.

Hardboard bats, sometimes called Masonite bats, are generally quite sturdy and they have a nice, rigid feel that some potters prefer. They’re also absorbent, which means they can help with drying the bottom of your pot and make it easier to remove. However, over time and with frequent use, hardboard bats can start to warp. This is because they absorb water, and the process of absorbing and then drying out can eventually cause changes in the shape. Also, they can develop small fissures and cracks that can harbor clay and be difficult to clean out.

Plastic bats, on the other hand, are non-absorbent. This makes them easier to clean and less likely to warp over time, but it also means they won’t help to dry out the bottom of your pot. In terms of durability, they can last for many years without showing signs of wear. However, they can be scratched by tools if you’re not careful, and those scratches can be hard to clean.

So, in terms of sheer longevity, plastic bats typically outlast hardboard ones. However, some potters prefer the feel and absorbency of hardboard bats. Like so many things in pottery, it really comes down to personal preference. You might even want to keep a few of each on hand for different types of projects or stages of the throwing process.

The secret on how do you properly attach wheel heads to a pottery wheel bat without damaging either one of them?

Affixing your wheel bat properly to the wheel head is a crucial step to ensure smooth, efficient pottery making without causing any damage. The process is pretty straightforward and follows these steps:

- Ensure Everything is Clean Before you attach anything, make sure both the wheel head and the bat are clean. This ensures a good connection and prevents any debris from causing imbalances or making the bat sit incorrectly.

- Align the Bat Pin Holes Every bat has holes in it that correspond with the bat pins on your wheel head. Align these holes with the pins.

- Secure the Bat Once the bat is on the wheel head, push it down onto the pins. You should feel it secure into place. Don’t force it, as this could potentially damage the bat or the wheel head.

- Double-Check the Alignment Once your bat is on, give it a spin. It should move smoothly. If it wobbles or is off-center, you’ll need to readjust.

- Start Throwing With the bat securely in place, you’re ready to start throwing. Apply your clay to the center of the bat and begin your process.

I never yank or pull too hard when removing the bat from the wheel head, and I always clean bats after use. A gentle touch and regular maintenance can significantly extend the life of both your bats and your wheel head.

My secrets for attaching and removing bats on a pottery wheel head quickly during production runs

Attaching and removing bats on a pottery wheel head can be time-consuming, especially during production runs. However, over my four decades of pottery making, I’ve picked up a few tricks to make the process more efficient.

- Use a Bat System Bat systems are designed to make the process of swapping out bats easier. They often have a master bat that remains on the wheel head, and you can quickly change the inserts as needed. It speeds up the process significantly.

- Prep your Bats Before starting, make sure all your bats are ready to go, clean, and their holes align properly with the bat pins. This way, you can easily swap them out when you need to, saving precious minutes.

- Smooth Transitions If you’re throwing similar items, try to standardize the amount of clay you use for each piece. This way, you won’t have to adjust your wheel or your positioning much between each bat.

- Removing the Bats Be careful but swift. Use a wire to cut any excess clay off the bottom of the piece, then gently lift the bat from the wheel head. It can be tempting to yank it, but this can cause damage.

- Stay Organized Have a dedicated place to put used bats and finished pieces. This ensures you aren’t fumbling around looking for space and keeps the workflow efficient.

Remember, everyone’s technique might be slightly different, so what works best for me might not work best for you.

Case Study: Meesh Switch’s Experience with Different Pottery Bats

To offer our readers real-world insights, we spoke with Meesh Switch, an artist deeply involved in the creative process and a seasoned potter. Meesh graciously shared her journey of experimenting with various pottery bat materials and the impact on her work.

The Experiment

Meesh decided to evaluate four types of pottery bats, Masonite, Plastic, Wood, and Composite—over a span of six months. She used each type for a variety of projects, from basic bowls to intricate sculptures.

Key Findings

Masonite Bats

- Pros: Excellent for small, quick projects and easy to clean.

- Cons: Tended to warp when exposed to moisture.

Plastic Bats

- Pros: Highly durable and easy to clean.

- Cons: The surface can be a bit slippery, making it challenging for larger projects.

Wood Bats

- Pros: Offered a natural, tactile feel, ideal for large, complex projects.

- Cons: Required regular maintenance to prevent warping.

Composite Bats

- Pros: Highly versatile and durable.

- Cons: The higher cost could be a barrier for some.

Meesh’s Recommendations

After six months of detailed testing, Meesh concluded that Composite bats (Medex or Masonite) offered the best balance between durability and versatility for her artistic needs. However, she emphasized that the “best” material can differ based on individual project requirements and personal preferences.

Conclusion

Meesh Switch’s case study provides invaluable insights into the practical considerations of choosing a pottery bat. Her experience serves as a real-world guide, helping you make an informed decision on the best material for your pottery endeavors.

Frequently Asked Questions

Q: What size is a standard pottery bat? A: A standard pottery bat typically measures around 12 to 14 inches in diameter. However, they can come in various sizes to accommodate different types of projects, and it’s always essential to verify the bat size compatibility with your pottery wheel.

Q: What kind of wood do you use for pottery bats? A: Many wooden bats for pottery are made from medium-density fiberboard (MDF) or marine-grade plywood. Both materials are chosen for their durability, stability, and slight water absorption qualities that are beneficial for pottery work.

Q: What is an alternative for pottery bats? A: If you don’t have a pottery bat, you can use a plaster bat, a piece of drywall, or even a tempered glass plate as alternatives. However, remember that each material will have its own set of characteristics affecting the clay workability.

Q: Do I need a bat for my pottery wheel? A: While it is possible to throw directly on the wheel head, using a bat offers several advantages. It allows you to remove your work easily without distorting the shape, enables drying and trimming off the wheel, and makes it possible to throw multiple pieces in a single session. Especially for beginners, using a bat can make the learning process easier and more enjoyable.

About the Author: Ed Shears

Hello, I’m Ed Shears, the creative force behind Artabys.com, a platform dedicated to promoting visual arts education and awareness. With a robust foundation in traditional pottery techniques, my true passion lies in creating unique ceramic wall art. Each piece I create is handbuilt with meticulous attention to detail, embodying originality and craftsmanship.

Credentials and Experience

- Education: A dedicated student of ceramic arts, my skills have been honed through rigorous training and hands-on experience.

- Artistic Philosophy: I believe in the unparalleled beauty of handcrafted original artwork, which not only adds a unique touch to living spaces but also resonates with the soulful touch of its creator.

- Achievements: I am a renowned author and contributor at Academia.edu and have showcased my artwork at Fine Art America since 2015.

For more about me and my work, feel free to visit my full artist page.

Expert and User Reviews From Artabys

Reviewer: Meesh Switch

Rating: ⭐⭐⭐⭐⭐

Testimonial: “As an artist deeply involved in the creative process, I found this article on pottery bats to be incredibly insightful. It not only covers the basics but also dives into the nuances that can make or break your pottery experience. A must-read for anyone serious about the craft!”

Reviewer: David Jackson

Rating: ⭐⭐⭐⭐⭐

Testimonial: “This article is a comprehensive guide that fills in the gaps where most tutorials fall short. It offers valuable tips on selecting the right pottery bat, which is often overlooked but crucial for any potter. The maintenance advice is a bonus that will surely extend the life of your equipment. Highly recommended for both beginners and seasoned potters.”

References

The Potter’s Studio Handbook: A Start-to-Finish Guide to Hand-Built and Wheel-Thrown Ceramics” by Kristin Muller Muller, Kristin, and Jeff Zamek. The Potter’s Complete Studio Handbook: The Essential, Start-to-Finish Guide for Ceramic Artists. Quarry Books, 2011.