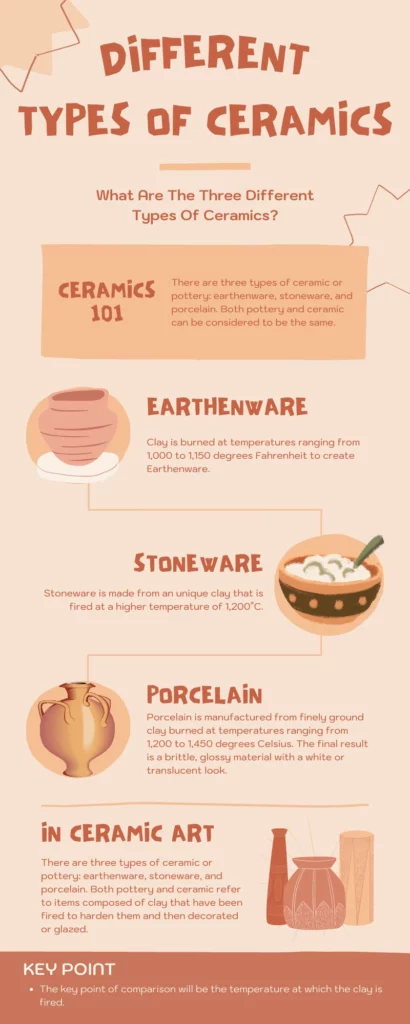

Ceramic or pottery may be divided into three categories: Earthenware, stoneware, and porcelain. Both pottery and ceramic are umbrella words for things made of clay, fired to hardness, and then decorated or glazed. The temperature at which the clay is fired will be the fundamental point of comparison between Earthenware, Stoneware, and Porcelain.

Main Types of Ceramics?

The main types of ceramics are Earthenware, stoneware, and porcelain. At various temperatures, various clay bodies mature or have been fired to the point where they are formed in their final state. different clay bodies mature at different temperatures. The more vitreous a clay body is, the higher it (the temperature and heatwork) needs to be fired.

During the firing the clay body vitrifies. After a clay body is vitreous, it indicates that when it is fired to maturity, no water may be absorbed into the clay. This is very important and significant since it greatly influences the clay’s freezing susceptibility. No water, no freeze, right?

Clay contains a lot of water by nature. Despite the fact that it seems to be dry, it nevertheless contains water. If I burn the clay too rapidly, the water will immediately change to steam and the clay will explode. And the last thing you want to happen in your kiln is for it to happen.

You may also have a damaged kiln in addition to damaged artwork or ceramics. Prior to burning, the clay should be bone dry or fully dry. The drying period for larger pieces will be longer than for smaller parts. When water inside the clay body is heated too quickly, it turns to steam, which can cause the clay to explode. When this occurs, clay particles are subjected to a heat shock.

Controlling the heat during bisque firing (getting the exact bisque temperature) is so crucial. When employing an electronic controller, however, I may set the kiln to gradually increase the heat. This gives me complete control over the firing sequence and temperature.

Many people who do this by hand will keep a fire log including firing cycles and time. Using an electron controller, however, I can administer heat in phases during the firing process. So, in a nutshell, it can heat gently (managing the entire fire) while allowing steam to leave without blowing up the clay.

I use the terms “low fire,” “mid fire,” and “high fire” are used to describe the temperatures at which clay bodies are fired. During your bisque fire, you’ll heat the clay to these temperatures. You’ll note that my list below only includes the most popular cone ranges. The temperature ranges are as follows:

- Low Fire (1828 F – 1945 F) – Cone 06 – Cone 04

- Cones 5 and 6 (2167 F – 2232 F) are in the middle of the fire

- Cone 8 – Cone 10 – High Fire (2280 F -2345 F)

There are three main types or major types of pottery and ceramic. These are earthenware (being the most common type), stoneware and porcelain.

Different Types of Ceramics

1. Earthenware

Earthenware is made of clay that is fired at temperatures ranging from 1,000 to 1,150 degrees Fahrenheit. This produces a hardened, brittle, and somewhat porous substance. Because earthenware has tiny pores through which liquid or air can pass, it can’t be utilized to hold water.

I apply a glaze to the piece before I fired it a second time in the kiln and rendered it waterproof.

Iron and other impurities are present in earthenware clay, allowing for optimum hardness at low temperatures. It’s porous, highly plasticized, and I like to work with it because it’s simple to use.

To quickly summarize: Because earthenware pots composed of clay fired at low temperatures are porous, they require many layers of glazing to retain water. Impure clays containing rock and sand particles are commonly used to make earthenware clay pots. Low fire clay is fired at a temperature of roughly 1950F, or cone 04, on average. Clay is commonly gathered from streams where it has settled and created clay deposits in which are used to create earthenware pots.

2. Stoneware

Stoneware is created from special clay that is baked at a higher firing temperature of 1,200 degrees Celsius. As a result, the material becomes more durable and has a denser, stone-like appearance. The completed product will be watertight and will not require glazing, unlike earthenware. Stoneware is fired at temperatures ranging from 2010 to 2370 degrees Fahrenheit (1100-1300C). This indicates stoneware is fired between cone 4 and cone 10 according to the cone system.

In its natural state, stoneware clay is a grey color. It is usually heated at high temperatures, resulting in a medium gray or brown hue. After the clay has been fired, it has become hard, thick, and stone-like.

The most popular type of clay used to manufacture dinnerware, and cookware is stoneware. Stoneware is made of hard, durable clay with minimal impurities, which makes it less porous than earthenware and therefore excellent for holding liquids without leaking.

3. Porcelain

Porcelain (Bone China) is made from refined clay that is fired at temperatures ranging from 1,200°C to 1,450°C. The end product is a brittle, lustrous substance that is frequently white and transparent in appearance.

Porcelain clay is a flexible material that may be used to create attractive and excellent art home accessories. Porcelain burns at a far higher temperature than other clays (up to 2550 degrees Fahrenheit). As a result of the fire, the material gets vitrified. Tableware is made of stoneware, which is fired at temperatures between 2100 and 2300 degrees Fahrenheit.

Porcelain is another type of clay, made mostly of pure kaolin or China clay. Porcelain clay has a low impurity content and hardens at severe temperatures. Porcelain is hard clay that may readily break. After burning, the surface of porcelain becomes smooth and glossy, obviating the necessity for glazing.

4. Bone China

In today’s world, this has taken the place of pure porcelain. It is the most durable form of porcelain. It also has a high resistance to chipping. It has incredible physical strength and produces a white, transparent outcome in most cases. Bone ash, kaolin, phosphates, and feldspar are all present.

Bone china is made from powdered bone ash, a type of porcelain that is less prone to damage like chipping. In addition, it has an ivory-white look.

Types of Clay for Pottery – The 5 Main Types of Ceramic Clay

The world of clay is vast and fascinating, and throughout my journey in pottery, I’ve come to know and love the subtle and not-so-subtle differences among the various clay bodies. Some of these were already discussed above so I tried yo provide additional information. Here are the 5 main types of ceramic clay:

- Earthenware. This is one of the oldest and most common types of clay. It’s often reddish due to its iron content but can also be white or gray. It’s porous and not as strong as other types, which makes it perfect for hand-building and low-fire pottery. Typically, it’s fired at a lower temperature and often used for decorative pieces and tableware.

- Stoneware. A favorite for many potters, stoneware is dense, strong, and durable, making it suitable for everyday kitchenware. Its firing range is quite broad, but it’s typically fired at high temperatures. Once fired, stoneware is non-porous, even without glaze. It can come in a variety of colors, including gray, brown, and tan.

- Porcelain. Known for its delicacy, smoothness, and strength, porcelain is highly refined and can be almost translucent when thin. It’s made from kaolin clay and is fired at the highest temperatures, making it non-porous. Its pure white color provides a great canvas for various glazing techniques.

- Ball Clay. A secondary clay, ball clay is super plastic and can be used in small amounts to increase the workability of other clays. It’s fine-grained and comes in a pale color, but due to its high shrinkage rate, it’s not typically used alone.

- Fire Clay. As the name suggests, this type of clay can withstand very high temperatures, making it perfect for creating refractory products like bricks, crucibles, and kiln linings. It’s sturdier than earthenware and can be tan or light gray.

Summary

Ceramic or pottery may be divided into three categories: Earthenware, stoneware, and porcelain. Both pottery and ceramic are umbrella words for things made of clay, fired to harden them, and then decorated or glazed. The temperature at which the clay is burned will be the fundamental point of comparison.

Ceramic Firing Techniques – Firing is a technique for creating ceramics that can withstand a lot of pressure. The firing takes place in a room with plenty of oxygen. There are two main ways for firing ceramics. The two ways are kilns and open firing. Firing is a critical stage in the ceramic process. It’s when clay changes from clay to functional pottery.

I always like to say to should start with a good base and then build up. This approach can also be applied to ceramic artwork and pottery. Always start with high-quality clay and in the end, I always have a high-quality finished artwork or pottery. The quality of the finished products will be determined by the quality and purity of the clay used to make them, although Stoneware and Porcelain will be the two more durable types of ceramic often used as dinnerware at home.

Definitions

Ball Clay

Ball clays are kaolinitic sedimentary clays that typically include 20% to 80% kaolinite, 10% to 25% mica, and 6 to 65% quartz. The content of localized seams in the same deposit varies, including the proportion of main minerals, accessory minerals (clay minerals), and carbonaceous elements like lignite.

Pottery Wheel

A potter’s wheel is a machine used to shape round ceramic ware in pottery. The wheel may also be used to reduce surplus body from cured ceramics and to add etched ornamentation or color rings.

Ceramics

The word ceramic comes from the Greek keramos, which means “pottery,” and is derived from an ancient Sanskrit root that means “to burn.” The word “burnt material” or “burned soil” was employed by the Greeks. As a result, the term was used to a product created by the effect of fire on earthy elements.

One of three major categories of solid materials is ceramics. Metals and polymers are among the various types of materials. A composite is a substance created by combining two or more of these elements to create a new material with qualities that cannot be achieved by traditional techniques. Steel reinforced concrete, steel belted tires, glass or fiber reinforced polymers (so-called fiber resins) used in boats, tennis rackets, skis, and racing cycles are examples of composites.

Ceramics are inorganic, non-metallic materials that are generally made from clays and other natural minerals, as well as chemically treated powders. Ceramics are crystalline materials made up of metallic and non-metallic components such as aluminum and oxygen (alumina- Al2O3), silicon and nitrogen (silicon nitride- Si3N4), and silicon and carbon (silicon carbide- Si3C) (silicon carbide-SiC). Glass is sometimes seen as a subcategory of ceramics. Glass differs from ceramics in that it is amorphous, meaning it lacks long-range crystalline organization. Silicon is also a popular type of ceramic. It has desirable chemical properties or chemical composition and is very abundant as it makes up about ninety percent of the Earth’s crust.

The majority of people associate ceramics with art, tableware, pottery, tiles, brick, and toilets. Traditional or silicate-based ceramics are the terms used to describe the goods described above. While traditional ceramics have played an essential role in society and continue to do so, a new class of ceramics has evolved that most people are unaware of. Space shuttle tile, engine components, prosthetic bones and teeth, computers and other electrical components, and cutting tools are just a few of the applications for advanced or technical ceramics.

Tang Dynasty

The Tang dynasty, also known as the Tang Empire, controlled China from 618 to 907, with an interregnum between 690 and 705. The Sui dynasty came before it, while the Five Dynasties and Ten Kingdoms era came after it. The shapes and themes of Tang dynasty ceramics demonstrate a global influence. A huge number of painted clay figures and dishes, as well as three-color glazed figurines and dishes, were manufactured. Production of white porcelain in northern China.

Mechanical Properties

The mechanical qualities of structural and architectural raw materials, as well as textile textiles, are critical. Fracture mechanics is a significant technique in current materials science for enhancing the mechanical performance of materials and components according to material scientists. It uses stress and strain physics, particularly elasticity and plasticity theories, to tiny crystallographic flaws present in actual materials to predict macroscopic mechanical failure of things. Fractography is commonly utilized in fracture mechanics to better understand the reasons of failures and to test theoretical failure predictions against real-life failures.

The majority of ceramic materials are ionic or covalently linked. A material held together by either type of bond has a tendency to shatter before any plastic deformation occurs, resulting in low toughness. Furthermore, because these materials are porous, the pores and other tiny flaws function as stress concentrators, lowering toughness and tensile strength even further. In contrast to metals’ more ductile failure modes, these factors combine to cause catastrophic breakdowns.

Plastic deformation is seen in these materials. However, because crystalline materials have a stiff structure, there are few potential slip systems for dislocations to migrate, therefore they deform slowly.

Ceramic material development has created the class of ceramic matrix composite materials, in which ceramic fibers are incorporated and specialized coatings build fiber bridges across any fracture to overcome the brittle behavior. This mechanism improves the fracture toughness of such ceramics significantly. Ceramic disc brakes are an example of a ceramic matrix composite material that has been made utilizing a specific process.

Six Types Of Clay Mined In The United States

- Kaolin (China clay) (High Kaolin content) – Kaolin is commonly used in the production of glossy paper. It’s also found in kaolin and morphine, a stomach pain reliever.

- Bentonite – Bentonite is used in a range of industrial applications, such as drilling mud and foundry sand, and it’s also used in pet waste absorbent products.

- Ball clay – Ball clay is a premium clay that is used in pottery, sanitary ware, roof tiles, ceramic tile, and wall and floor tiles.

- Fuller’s Earth – Pet waste products are also made with Fuller’s Earth.

- Fire clay – Fire clay is used in refractory bricks (used as a thermal insulator) and cement.

- Common Clay – Bricks, cement, and aggregate are all made from common clay.

What distinguishes ceramic from other materials?

- Electrical and thermal conductivity are both low.

- Melting points that are high.

- They don’t react with other compounds.

- They’re durable and long-lasting.

- Hardness and strength in spades.

Kiln Brick

Kiln bricks, also known as Fire Bricks or Refractory Bricks, are made of a refractory ceramic substance (physical properties) that can withstand high temperatures. A common application of the use of ceramics is they are used as refractory materials and as an electrical insulator. The bricks line the inside of a kiln and serve as good insulators, decreasing heat loss and maximizing energy efficiency. Kiln bricks are available in a range of shapes, sizes, and materials, including soft and hard.

Kiln bricks are divided into two categories: hard brick and soft brick. Hard bricks are often quite strong and dense, and they’re widely used as structural support in kilns. These bricks can withstand a broad variety of temperatures and weather. Because soft bricks are less thick, they provide better insulation than hard bricks. These may be found in electric kilns and any other kiln that has to be insulated to avoid heat loss.

Bricks come in a variety of forms, but the most common and manily used is rectangular, measuring 9” x 4.5” x 2.5”. Rectangular bricks measuring 9” x 4.5” x 3” are gaining popularity because the 3” firebrick adds insulation and improves energy efficiency.

Zirconium Oxide

Zirconium dioxide, sometimes known as zirconia, is a white zirconium crystalline oxide. Baddeleyite is the mineral’s most common form, which has a monoclinic crystalline structure. Zirconium dioxide, sometimes known as zirconia, is a common ceramic oxide. It’s used in abrasive materials, dental bridges and crowns, paints and lacquers, fuel cell membranes, and joint implants, among other things.

Tungsten Carbide

Is a type of ceramic. Tungsten carbide is a chemical compound made up of tungsten and carbon atoms in equal proportions. Tungsten carbide is a fine gray powder in its most basic form, although it may be crushed and shaped into forms.

Titanium Carbide

Titanium carbide, or TiC, is a refractory ceramic substance that is exceedingly hard and comparable to tungsten carbide. It has a black powder appearance and a sodium chloride crystal structure.

Aluminum Oxide

Aluminium oxide, is a chemical compound made up of aluminum and oxygen. It’s the most common of various aluminum oxides (metal oxides), and it’s officially known as aluminum(III) oxide. The most common oxide ceramic material is alumina (Aluminum Oxide). Spark plugs, tap washers, abrasion-resistant tiles, and cutting tools are only a few examples of its uses. Monolithic and brick refractories are also made with extremely huge tonnages. for an example, Ballistic armored vests made of ceramics like alumina and boron carbide have been used to deflect high-velocity rifle fire. Also sculpting clay contains aluminum oxide and other organic matter.

Thermal Shock

Thermal shock is a form of mechanical force that occurs quickly. A mechanical load is defined as a load induced by a quick change in temperature at a specific place. It may also be used to a thermal gradient, in which various portions of an item expand at different rates.

References

American Ceramic Society – Advance ceramic materials – ceramics.org https://ceramics.org/

Wheat, J. B., Gifford, J. C., & Wasley, W. W. (1958). Ceramic variety, type cluster, and ceramic system in Southwestern pottery analysis. American Antiquity, 24(1), 34-47. https://www.cambridge.org/core/journals/american-antiquity/article/abs/ceramic-variety-type-cluster-and-ceramic-system-in-southwestern-pottery-analysis/4A93039852CF41E43893FFD2A8589FFC

Dietler, M., & Herbich, I. (1989). Tich Matek: The technology of Luo pottery production and the definition of ceramic style. World archaeology, 21(1), 148-164. https://www.tandfonline.com/doi/abs/10.1080/00438243.1989.9980096

Smith, R. E., Willey, G. R., & Gifford, J. C. (1960). The type-variety concept as a basis for the analysis of Maya pottery. American Antiquity, 25(3), 330-340. https://www.cambridge.org/core/journals/american-antiquity/article/abs/typevariety-concept-as-a-basis-for-the-analysis-of-maya-pottery/A54E9A1976D18F72606A30DAC54E190B