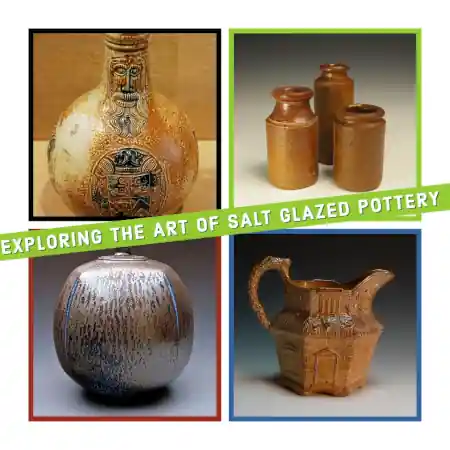

Salt glazed pottery is a type of ceramics that is made by applying a layer of salt to the surface of the clay before firing. The salt reacts with the silica in the clay and creates a glaze that gives the pottery a hard, glossy surface. The glaze provides a barrier against water. The unique color variations and distinctive crackled appearance.

Discovering the History and Craftsmanship of Salt Glazed Pottery

Clay is combined with other ingredients including feldspar, kaolin, and ball clay to create salt glazed pottery, a type of ceramic.

Salt is sprinkled over the wet clay’s surface during the firing process, which causes the salt to evaporate and interact with the clay’s silica.

A glossy, hard glaze is produced as a byproduct of this reaction, giving the pottery its distinct appearance and providing moisture resistance.

Salt glazed pottery is used for both functional and ornamental purposes, including jars, jugs, crocks, drainpipes, and decorative pieces.

The glaze can vary in color from light to dark blue-gray, and it is frequently marked by a network of fine fractures known as “crazing.”

What Are The Different Types Of Salt Glazed Pottery?

Three different ceramic materials—earthenware, stoneware, and porcelain—can be used to create salt-glazed pottery.

The earliest and most fundamental type of ceramics is earthenware. It is formed from a combination of clay and other natural materials and is fired at a low temperature, producing a porous and somewhat soft substance. Typically, practical goods like jars and jugs are made of earthenware salt-glazed pottery.

Stoneware is a type of ceramic that is fired at a higher temperature than earthenware and is made from a combination of clay and other elements. The end result is a material that is denser, stronger, less porous, and more moisture resistant. For storage containers and decorative items, stoneware salt-glazed pottery is frequently employed.

Kaolin, feldspar, and ball clay are combined to create porcelain, a form of ceramic that is fired at very high temperatures. As a result, a tough, non-porous material that is extremely impervious to moisture and stains is produced. Vases and figurines made of porcelain salt glaze are typical examples of decorative porcelain pottery.

What Are The Different Techniques Used To Create Salt Glazed Pottery?

Several processes, like as firing, staining, and painting, are combined to create salt-glazed pottery.

In order to make the finished product, the pottery must be heated to a high temperature in a kiln during the firing process. Salt is applied to the pottery’s surface prior to firing, which causes the salt to evaporate and interact with the silica in the clay. The glossy, firm finish that gives salt-glazed pottery its recognizable appearance is produced by this process.

Prior to or following firing, staining entails coloring the pottery. Stains can be incorporated into the clay before it is formed, or they can be added to the pottery’s surface with a brush or spray. A variety of colors and effects, such as solid colors, graduated color shifts, and textured surfaces, can be produced with stains.

After firing, decorative elements are added to the pottery’s surface to create painting. Paint can be used to make a variety of designs, including patterns, images, and writing. It can be applied with a brush, stencil, or other tool. To establish the design and make it more lasting, the paint can be fired in a kiln; alternatively, it can be left unfired for a more delicate look.

These methods are combined to produce one-of-a-kind, distinctive pieces of useful and adornment-worthy salt-glazed pottery.

What Are The Different Styles Of Salt Glazed Pottery?

Pottery with a salt glaze can range from straightforward, useful items to intricate, colorful works of art.

The glaze color and design of simple salt-glazed pottery are often homogeneous. This design is well-known for its durability and resistance to moisture and is frequently used for practical goods like jars, jugs, and drainpipes.

Intricate patterns like relief carving, incised lines, and painted decorations are frequently found on decorative salt-glazed pottery. This design is renowned for its distinctive color and texture and is used to make decorative items like vases, figurines, and architectural elements.

Hand-painted designs, like as portraits, landscapes, and floral themes, can be found on certain salt-glazed pottery. These items, which are frequently unique works of art, are highly prized for their fine craftsmanship and aesthetic appeal.

Finally, there are styles that combine many methods to produce intricate and detailed works of art, including staining, painting, and carving. These items are highly coveted by collectors and enthusiasts and frequently have a variety of hues and textures.

Salt-glazed pottery is a versatile and classic kind of ceramic art that has been favored for generations, regardless of the style.

How Does Salt Glazed Pottery Differ From Other Ceramic Glazes?

Method of Glaze Formation

Other ceramic glazes are normally applied to the pottery’s surface before firing, whereas salt-glazed pottery is made by sprinkling salt over the surface of the wet clay during the firing process.

Appearance

Unlike other ceramic glazes, the salt glaze produces a singular glossy surface with tiny fissures known as “crazing.” The glaze’s hue can range from pale to dark blue-gray.

The toughness and resistance to moisture of salt-glazed pottery make it perfect for practical goods like jars, jugs, and drainpipes.

Versatility

A variety of utilitarian and decorative uses are possible with salt-glazed pottery since it may be manufactured from many ceramic materials, such as earthenware, stoneware, and porcelain.

Historical Significance

Salt glazed pottery has a lengthy history that dates back to the European Middle Ages, and it has contributed significantly to the growth of ceramic art.

What Is The Salt-Glazing Process Used To Produce Watts Pottery?

A time-honored technique from medieval Europe is the salt-glazing procedure used to create Watts Pottery. Forming the pottery, glazing it, and firing it are just a few of the processes in the procedure.

A mixture of clay, water, and additional ingredients like feldspar or kaolin is used to make the pottery into the desired shape.

After that, a glaze is applied to the pottery, often made up of feldspar, kaolin, and silica. The pottery is then put inside a kiln, which gradually raises the temperature.

Salt is put on top of the pottery before it is fired, which happens when the kiln reaches a high temperature. A layer of glass is formed on the pottery’s surface when the salt combines with the silica in the glaze, causing it to evaporate. The glaze’s characteristic blue-gray hue is also a result of the salt.

This procedure yields a long-lasting, glossy glaze that is moisture-resistant and gives Watts Pottery its distinctive appearance. High-quality, useful, and ornamental ceramics are being produced using the same ancient salt-glazing technique that has been used to make Watts Pottery for many years.

How Are Salt Firings Typically Conducted, And What Conditions Must Be Met For Successful Results?

The last stage of salt glazing is salt firing, which is normally done in a kiln.

Temperature

The kiln must reach a high temperature, often between 1280 and 1320 degrees Celsius (233 and 2400 degrees Fahrenheit), for the salt to evaporate and interact with the glaze’s silica.

Humidity

During the firing process, the kiln needs to be maintained reasonably dry because too much moisture can mess up the glaze.

Application of salt

The salt must be evenly distributed across the pottery’s surface, as uneven distribution might lead to uneven glazing.

Timing

In order for the salt to interact with the silica, the glaze must be melted but not totally fused when it is applied.

Atmosphere

The atmosphere within the kiln needs to be carefully managed because it might have an impact on the glaze’s color and consistency.

Cooling

Since rapid cooling can put stress on the glaze and the pottery itself, the pottery must be chilled gradually and uniformly.

Are There Any Distinct Salted Patterns Or Textures That Differentiate Salt Glazed Pottery From Others?

Salt glazed pottery is distinguished from other pottery by its distinct salty patterns and textures. As a result of the distinctive salt glazing process, these patterns and textures can include:

Craze Lines

Salt-glazed pottery frequently exhibits tiny cracks in the glaze that are known as “crazing.” Depending on the temperature and humidity levels during the firing process, these lines may be subtle and delicate or huge and bold.

Temperature changes, variations in the thermal expansion of the glaze and body, and the presence of contaminants in the clay or glaze are only a few of the causes of craze lines. Typically, they are seen as character traits that enhance the piece’s attractiveness rather than as flaws.

Iridescent Surfaces

Due to the glossy surface of the glaze, salt-glazed pottery can seem iridescent.

The layering of various hues and the interference of light waves at the glaze’s surface are what cause the iridescence. Depending on the angle of the light and the observer’s viewpoint, the colors can range from blues and greens to pinks and purples.

Many collectors and enthusiasts view iridescence as a desirable quality in salt-glazed pottery. The pieces’ iridescent look enhances their beauty and individuality, setting them apart from other types of ceramics.

Pitting

Small pits or dimples may appear on the glaze’s surface as a result of the salt and silica in the glaze reacting.

The clay’s composition, the firing’s temperature, and the amount of salt in the glaze can all affect the pits’ size, form, and depth. Pit marks can range in size from tiny and hardly perceptible to larger and more obvious.

Pitting is thought to give salt-glazed pottery more personality and charm, giving each piece a distinctive appearance.

Streaks

Due to variances in the dispersion of salt during the firing process, the glaze may exhibit blue-gray color streaks.

Depending on the temperature and humidity levels during the firing, streaks might range from light gray to dark blue and be fine or prominent. Variations in the glaze or clay body’s composition may also be to blame.

Each piece of salt-glazed pottery is unique and has streaks that give character and charm. Many potters and collectors think they are a desirable quality since they give the glaze’s surface more depth and interest.

Salt-glazed pottery has distinctive patterns and textures that set it apart from other types of ceramics and give it a distinctive appearance. Each piece of salt-glazed pottery is genuinely one-of-a-kind thanks to the differences in the patterns and textures that give it personality.

Is There A Specific Type Of Clay Pot Best Suited For Salt Glazing?

The ideal clay for salt glazing is a particular kind of clay. A high-silica clay body, such stoneware or porcelain, with a low shrinkage rate and a strong tolerance to thermal shock, is often used to make salt-glazed pottery.

The glaze forms when silica combines with salt during firing to create a hard, glossy surface, therefore the clay body’s high silica concentration is crucial for this process. Low-silica clays, like earthenware, are less ideal for salt glazing because they shrink more quickly and are more susceptible to heat shock, which can cause cracking or crazing of the glaze.

What Safety Measures Should Be Taken When Setting Up Kiln Shelves For Salt Firing Processes?

- Wear protective clothes, such as gloves and a dust mask, when installing kiln shelves to avoid coming into contact with salt and other caustic materials.

- Kiln shelves should be clean and clear of any leftover material from previous firings, since this might lead to unintended reactions during the firing process.

- Kiln shelves should be constructed of high-fire stoneware or cordierite, which is compatible with the corrosive salt-firing materials.

- To provide for optimal ventilation and the circulation of heat and gases, kiln shelves should be positioned with enough room between them.

- Kiln shelves should not be overloaded because this can cause uneven heating and cracking of the pottery as well as the kiln shelves.

How Do Sodium Vapors Contribute To The Unique Characteristics Of Salt Glazed Pottery?

By reacting with the silica in the clay to create a glaze on the pottery’s surface, sodium vapour help to create the distinctive qualities of salt-glazed pottery. The silica in the clay body reacts with the sodium and chlorine fumes produced when salt is supplied to the kiln and allowed to vaporize at high temperatures during the firing process.

A hard and glossy glaze is formed on the pottery’s surface as a result of the reaction melting the silica. The glaze’s salt content contributes to its particular color and texture and can cause changes in the glaze’s appearance, including streaks, pitting, and iridescent surfaces.

The sodium in the glaze functions as a flux, assisting in the bonding of the glaze to the clay body and enhancing the pottery’s durability and resistance to stains and moisture.

Are There Any Special Techniques Involved In Creating Pieces With This Specific Type Of Pottery Glaze?

When making pottery with salt glaze, there are specific processes that must be followed.

Throwing and shaping the pottery: The pottery needs to be thrown and shaped so that the glaze may spread uniformly over the surface without leaving any bare spots or causing glaze fractures.

To ensure that the glaze adheres properly to the pottery’s surface and does not crack, the pottery’s surface should be cleaned and polished.

The glaze can be applied to the pottery’s surface by brushing, dipping, or pouring it. It is important to take care to avoid any unglazed or drip-free areas when applying the glaze.

To create the sodium and chlorine vapors that react with the silica in the clay body to make the glaze, the pottery should be fired in a kiln with salt added to the firebox. To guarantee that the temperature and firing time are suitable for the particular clay type and glaze being used, the firing process is closely monitored.

Can Traditional Methods Of Decorating Clay Pots Be Applied To Salt Glazed Pottery?

Salt-glazed pottery can be decorated using conventional techniques, but because of the material’s unique properties, the results could be surprising. Because of the salt glaze, salt glazed pottery has a distinctive surface texture and look. As a result, techniques like painting, staining, and slip trailing may not appear as they would on other types of ceramics when applied to salt-glazed pottery.

The ability of some decorating techniques to cling to the surface of salt-glazed pottery may be impacted by its durability and resistance to moisture. For instance, certain glazes or stains could not stick to the salt glaze very well and eventually peel or flake off.

Conclusion And Summary

Ceramics with salt glazes are prized for their distinct texture, toughness, and moisture resistance. When salt is added to the kiln during firing, a chemical reaction occurs between the salt and the silica in the clay body, forming a glaze on the surface. A tough, smooth surface that is long-lasting and moisture-resistant is produced by this procedure.

Salt-glazed pottery comes in a variety of designs, from straightforward, practical items like jars and mugs to more aesthetically pleasing items like vases and figurines. Pottery with a salt glaze has some distinctive qualities, such as:

- Salt-glazed pottery has a distinctive surface texture that is smooth and resilient while also having a somewhat gritty feel.

- Salt-glazed pottery is renowned for its sturdiness and resistance to moisture, making it an excellent choice for items like flower vases that will be exposed to moisture.

- Depending on the clay body used and the firing circumstances, salt-glazed pottery can have a unique color that can range from light gray to blue-gray.

- Painting, staining, and slip trailing are just a few of the decorative options available for salt-glazed pottery.

To sum up, salt glazed pottery is a remarkable and long-lasting style of ceramic that is renowned for its peculiar texture, moisture resistance, and striking color. Salt-glazed pottery comes in a variety of designs, from straightforward, practical items to more aesthetically pleasing items, giving it a flexible choice for a variety of uses.

My Favorite Salt Glaze Artists

Mary Louise McLaughlin

American artist Mary Louise McLaughlin is renowned for her useful salt-glazed pottery. Her work is influenced by conventional pottery forms and has a straightforward, rustic aesthetic that highlights the salt glaze’s organic texture and color.

John Hesselberth

John Hesselberth is an American potter who creates incredibly complex and intricate salt-glazed objects. He is renowned for his elaborate designs, which are made with slip trailing and other artistic methods and include landscapes and abstract patterns.

David Green

David Green is a well-known English potter who creates pieces with distinctive salt glazes and bold, graphic motifs that stand out against the salt glaze’s organic texture.

Jack Troy

Troy, an American potter, is renowned for his practical salt-glazed pottery, which draws inspiration from conventional pottery patterns. He is renowned for his straightforward, rustic aesthetic and emphasis on form and function.

Epilogue

Salt glazed pottery is a type of ceramic ware that is fired in a kiln using a vapor glazing technique. During the firing process, salt is introduced into the kiln, which vaporizes and combines with the silica in the clay body to create a glassy, waterproof coating on the surface of the pottery. This process is often carried out in a wood-fired kiln and is sometimes referred to as soda firing.

The salt glazing process results in various shades of orange, brown, and gray, and can be enhanced by the addition of manganese oxide, iron oxide, and cobalt oxide. The glaze is not applied evenly, so the resulting patterns on the pottery can be unique and unpredictable.

Salt glazed pottery is typically made in selected individual pots by skilled potters. One of the most famous salt glaze pottery manufacturers is Royal Doulton, which was founded in the mid-19th century in England.

Salt glaze pottery has a long history in the United States, particularly in New York and New England, where it was used to produce beer steins and other drinking vessels. The famous “Bartmann’ Jug” is an example of salt glaze pottery, featuring a pewter lid and a surface blush that is created by the steel angle against which it is fired.

To create salt glaze pottery, a sodium silicate or sodium bicarbonate solution is applied to the ware body before it is fired. The salt is then introduced into the kiln at a high temperature, where it vaporizes and reacts with the silica in the clay body. The process results in a glassy coating on the surface of the pottery, which is waterproof and translucent.

Salt glaze pottery is highly durable and can withstand harsh conditions. To achieve a desired effect, potters may use hydrochloric acid to etch the surface of the pottery or the potter’s wheel to create intricate patterns. Workshops and studios today continue to use salt glazing techniques to produce unique and beautiful ceramic pieces.

George Tinworth

This technique was developed in the Rhineland area of Germany in the 15th century and was later brought to England by German potters. Salt glazing produces a glassy, orange-peel texture on the surface of the pottery, which is achieved by the sodium in the salt reacting with the silica in the clay body.

In the 19th century, the famous George Tinworth created a number of salt-glazed stoneware pieces for the Royal Doulton company. John Doulton and the pottery firm Errington Reay were also known for their production of high-quality salt glazed pottery. The technique was particularly popular in New York and New England, where it was used to make beer steins, jars, and jugs.

During the salt glazing process, salt is introduced into the kiln at a high temperature, which creates a vapor that fills the firing chamber. As the salt vapor comes into contact with the hot ware body, it reacts with the surface of the pottery, creating various shades of orange-peel texture. The surface of the pottery may also have a surface blush due to the addition of manganese, iron, or cobalt oxide.

Stephen Green

The pottery is selected individually to be salt glazed, and the salt is introduced to the kiln only once the pots have reached a specific temperature. The technique is known for producing unique and varied effects, with no two pieces being exactly the same.

Potteries such as Stephen Green also use a soda firing technique that is similar to salt glazing. This method involves the introduction of sodium bicarbonate and sodium silicate into the kiln at a high temperature to create a glassy, translucent surface on the pottery.

After firing, salt glazed pottery may be decorated with designs, but the glassy coating is so hard that it resists glaze, so the decorations are often limited to pewter lids, steel angles, or other non-glazed materials. The pottery can also be etched with hydrochloric acid to create intricate designs.

Salt glazing has been used in workshops and production for centuries, and the translucent effect on the pottery is highly prized in the decorative arts. Today, salt glaze pottery is still made by individual potters and some larger companies, and the technique continues to be celebrated for its unique beauty.

References

By Picture taken by Marcus Cyron – Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=26778471

By Theroadislong – Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=23256287

By John dermer – Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=26249378

By Theroadislong – Own work, CC BY 3.0, https://commons.wikimedia.org/w/index.php?curid=13265899

Video – en.wikipedia.org/wiki/File:Salt_kiln.webm