It’s clay that has been given shape but not yet fired in a kiln. Greenware is the stage where it contains water and is shaped and molded into its ultimate form. It’s still malleable clay. Once fired, clay is no longer Greenware. Greenware clay is highly fragile and weak since it contains a lot of moisture. Greenware is dried mud with little value or practical application.

What Is Considered Greenware?

Greenware refers to clay pieces that have been formed but have not yet been bisque fired, converting them from clay to ceramic. Unfired pottery is referred to as Greenware.

Ceramic Firing Techniques – Firing is a technique for creating ceramics that can withstand a lot of pressure. The firing takes place in a room with plenty of oxygen. There are two main ways for firing ceramics. The two ways are kilns and open firing. Firing is a critical stage in the ceramic process. It’s when clay changes from clay to functional pottery.

What Is The Difference Between Bisque And Greenware?

The distinction between Greenware and bisque is that when manufacturers or artisans pour Greenware, they are simply combining solutions and clay together to create a slip clay. Bisque is clay that has been fired at a high temperature in a kiln.

What Is Greenware Used For?

Greenware is the first step in creating ceramic art. Greenware has no practical use until it’s fired in a kiln. Greenware is defined as an unfired clay object or body that was cast (poured) from a purchased or manufactured mold. Greenware’s next step is to dry, clean, paint, and/or glaze the clay body before firing it in a kiln.

What Is Raku Firing Technique? – Raku firing is a type of low-temperature firing. While the pots are still hot and the glaze is still molten, the pottery is taken from the kiln. Stoneware clay is frequently used to make raku. Read the article to discover even more interesting facts about raku.

Is Low Fire Clay Food Safe? – When covered with a food-friendly glaze, low-fire clay is safe to eat. Unglazed clay surfaces may be considered food safe when covered with a food-friendly glaze and fired to full maturity because the clay particles vitrify sufficiently. However, you should read the entire essay since there are a few caveats.

Handmade Ceramic Fish Wall Art – Colorful ceramic fish wall hanging.

What Are The 3 Types Of Ceramics? – Ceramic or pottery may be divided into three categories: Earthenware, stoneware, and porcelain.

What Is Dry Greenware?

The word “bone dry” is used to describe and identify Greenware clay pottery that has dried as much as possible before its bisque firing. When handled, bone dry Greenware has a room temperature feel to it, rather than being cool to the touch.Greenware should be dry before it’s first firing otherwise it may crack during bisque firing.

Greenware Stages

1. Original Greenware Stage

Greenware in it’s original form is very malleable and moist. this is the stage when the basic form is constructed. At this stage, Greenware can still be worked by adding more water or clay so that it softens and then can be easily reshaped. However one important note is that Greenware should not be fired in the kiln. It should dry out first and be in a bone dry state otherwise it could crack or break.

2. Leather Hard Stage

In this stage the Greenware still have some moisture and bodies can be slipped together or joined. In addition cleaned up can be done and relief or impressions can be made into the clay surface.

3. Bone Dry

Greenware in the bone dry stage is when the clay is completely hardened and ready to be fired.

What’s The Process

For Greenware, the drying process is critical. Until it is bone dry, it can’t be fired in the kiln, or it can deform or break in the kiln. Your Greenware needs to be carefully dried and in the process make sure all parts of the piece are dried evenly. It is important not to force-dry pottery in an attempt to speed up the drying process by blowing hot air on it. If you rush the process Greenware will crack. It’s in this stage where I do most of the handcrafted ceramic work.

I am well aware of how fragile Greenware is due to I have broken many pieces in creating ceramic artwork. Greenware can be in different stages. For example it can be wet, damp, soft leather-hard, leather-hard, stiff leather-hard, dry, and even bone dry. These are examples of different drying stages of Greenware.

How To Dry Greenware

Usually how I dry my Greenware is on racks and shelves allowing air to circulate between objects. Pieces need to be separated from each other otherwise they might end up melding together.

The drying process goes through several stages like I already mentioned from when it is still visibly damp to when it has dried enough to handle without deformation. And then finally to a final bone dry stage. When it’s in this stage the bone dry stage the art piece will feel warmer to the touch and you will visibility see it is much drier due to the color change. It will mist likely change to slightly lighter color of clay.

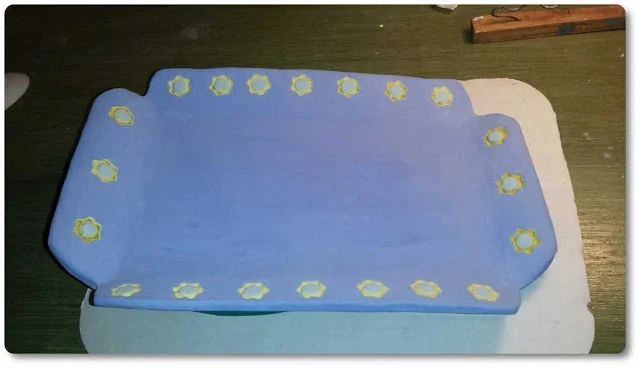

How To Decorate Greenware

I like to decorate my Greenware while it is drying in a state where is can support it’s own weight. While it’s in the Greenware stage or state I also sometimes add a glaze and then it will be fired. This is where I add color and texture to my artwork.

Definitions

China Clay

Kaolinite, often known as china clay, is a type of clay mineral. It is a valuable industrial mineral with numerous applications. There are two layers of silica in this material, one of which is a tetrahedral sheet of silica that is joined to the other by oxygen atoms, and one of which is an octahedral sheet of alumina octahedral.

Ball clays are kaolinite-rich sedimentary clays that typically include 20–80 percent kaolinite, 10–25 percent mica, and 6–65 percent quartz. They are used in a variety of applications. Localized seams within the same deposit differ in composition, including the amounts of main minerals, accessory minerals, and carbonaceous elements such as lignite found in the seams.

In addition to being a vital ingredient in the production of china and porcelain, they also used kaolin in the production of paper, rubber, paint, and a variety of other items. We also know kaolin as china clay.

Glaze

Glazes are made out of a combination of silica, fluxes, and aluminum oxide. Silica is the structural component of the glaze, and if heated to a high enough temperature (melting point), it can transform into glass. Because its melting temperature is too high for ceramic kilns, silica is coupled with fluxes, which are chemicals that prevent oxidation, to lower the melting temperature.

Six Types Of Clay Mined In The United States

- Kaolin (China clay) (High Kaolin content) – Kaolin is commonly used in the production of glossy paper. It’s also found in kaolin and morphine, a stomach pain reliever.

- Bentonite – Bentonite is used in a range of industrial applications, such as drilling mud and foundry sand, and it’s also used in pet waste absorbent products.

- Ball clay – Ball clay is a premium clay that is used in pottery, sanitary ware, roof tiles, ceramic tile, and wall and floor tiles.

- Fuller’s Earth – Pet waste products are also made with Fuller’s Earth.

- Fire clay – Fire clay is used in refractory bricks (used as a thermal insulator) and cement.

- Common Clay – Bricks, cement, and aggregate are all made from common clay.

What distinguishes ceramic from other materials?

- Electrical and thermal conductivity are both low.

- Melting points that are high.

- They don’t react with other compounds.

- They’re durable and long-lasting.

- Hardness and strength in spades.

Salt Glaze

What is a salt glaze, and how does it work? The term “salt glaze” refers to a glaze made of salt. When common salt is thrown into the kiln during the higher temperature stage of the firing process, it produces a glaze that is shiny, translucent and has a slightly orange-peel-like texture. This glaze is applied to pottery that is typically stoneware.

Thermal Shock

A thermal shock is a form of mechanical force that occurs quickly. A mechanical load is defined as a load induced by a quick change in temperature at a specific place. It may also be used to a thermal gradient, in which various portions of an item expand at different rates.

Electric Kiln

An electric kiln is a high-temperature heating chamber used to convert materials. A kiln uses a method that has been around for thousands of years to harden ceramic bodies. When clay is heated (baking clay) to the right temperature, it becomes hard enough to create tiles and vessels. Glazes that are burned on top of the clay create permanent decorations.

Some electronic kilns have a scheduler that controls the firing schedule from beginning to end automatically.

Gas Kiln

The most common form of fuel kiln nowadays is a gas kiln.

Kiln Furniture

Kiln furniture is used in the creation of specific parts, such as ceramic or metal components, and is employed in the heating procedures of such items. Kiln furniture components are wearable elements that must be replaced regularly because of the thermal, mechanical, and chemical stresses that occur during operation.

Firing Schedule

It is the series of predetermined stages that the kiln proceeds through from the time it is turned on to the time it is either turned off or has cooled down enough to unload, which is referred to as the firing schedule. It is determined by changes in the kiln environment or the firing ramp that these transformations occur.

Clay Drying

Wet – This means that it has just come out of the bag. It is still capable of being manipulated and molded without suffering a significant fracture.

Leather firm – The clay has now become substantially stiffer than before. When the clay is bone dry, the color of the clay will become significantly lighter.

Metallic Glazes

Metallic Glazes have a glossy finish that ranges from shiny to matte, and they can transform commonplace surfaces into striking works of art. Metallic Glazes are ideal for usage as a Raku glaze because of their metal-like appearance and consistency.

Cone 06

Temp at 108F per hour ramp temp is commonly used for Bisque and Low fire glaze.

Leather Hard

The term “leather hard” refers to a certain stage of drying that occurs when a pot or other clay object is made. The clay is still obviously damp at this point, but it has dried sufficiently to be able to be handled without deforming during handling. The clay can be gouged or incised without breaking, but it will not take the impressions of the gouges or incisions. A further refinement of the leather hard stage can be achieved by dividing it into three stages: soft leather-hard, leather hard, and stiff leather hard.

Casting Slip

Casting, sometimes known as ‘slip casting,’ is a process that is most commonly utilized in the field of geopolymers because of its ease of application. In this process, complicated shapes are created from a suspension that is poured into a mold. When using geopolymers, the suspension is made up of raw ingredients in powder form that have been distributed in a liquid, which in this case is water.

Nepheline Syenite

In the creation of ceramic and glass products, nepheline syenite is used to replace feldspar as a filler material. It is possible that the feldspar in nepheline syenite is cryptoperthite, or that it is a combination of albite and microcline. Sodalite or cancrinite may be used in place of nepheline in some cases, either entirely or in part.

Kiln Atmosphere

What exactly is the kiln atmosphere? This shows that oxygen from the surrounding air was present within the kiln chamber during the firing process. This firing does not bring the colors of the clay and glaze out to their full potential.

What are the two most basic sorts of kiln atmospheres? To put it simply, there are two types of kilns: intermittent and continuous, both of which are enclosed in an insulated box with a controlled internal temperature and atmosphere. It is common to refer to a continuous kiln as a tunnel kiln because it is lengthy and only the core piece is directly fired.

Bisqueware

Unfinished clay or pottery is called Bisqueware. Bisqueware is clay that has been fired in a kiln for the first time. “Biscuit” or “bisc” is what potters commonly refer to as Bisqueware ceramic. Bisqueware is not in its final state. It needs to be fired again before it’s in its ultimate state.

Potters Wheel

Slab Roller

What is the purpose of a slab roller? Slab Rollers make it possible to produce clay slabs quickly and efficiently (slab construction), which can be used in handbuilding and sculpting as well as as additions to wheel-thrown forms. Despite the fact that clay slab rollers are simply industrial-sized rolling pins, there are various advantages to employing a slab roller rather than a rolling pin in the construction industry.

References

Sparkes, B. A. (1991). Greek pottery: an introduction. Manchester University Press. https://books.google.com/books?hl=en&lr=&id=ntlRAQAAIAAJ&oi=fnd&pg=PR11&dq=introduction+to+making+pottery&ots=tI51GYEokc&sig=Q5IgHYAVFZC-2dPxnByim6-I3s0#v=onepage&q=introduction%20to%20making%20pottery&f=false