What Is The Definition of Bisqueware?

Unfinished clay or pottery is called Bisqueware. Its clay that has been fired in a kiln for the first time. “Biscuit” or “bisc” is what potters commonly refer to as Bisqueware ceramic. Bisqueware is not in its final state. It needs to be fired again before it’s in its ultimate state.

At this stage, Bisqueware acts like a sponge. When dipped into a glaze, it will absorb water and be coated with a glaze. The longer you let the bisque piece soak in the glaze, the more water it will absorb until the piece is finally saturated. It is then fired again and becomes a ceramic material. Click here for more information on examples of ceramic materials.

Bisqueware is clay that has had its initial firing in a kiln. Bisqueware ceramic is usually referred to as “biscuit” or “bisc” by potters. Bisqueware isn’t quite finished. Before it reaches its final form, it must be fired once more. It is then burned one more, resulting in a ceramic body or it’s final form.

What’s The Difference Between Bisqueware And Greenware?

Bisque is a term used to designate a type of pottery known as bisqueware. It can also refer to a method of firing clay, such as a bisque firing. Before it is fired for glazing, bisque is sometimes referred to as ‘pre-firing’ pottery ware. Greenware refers to unfired pottery.

What is unfinished pottery and Greenware? To learn more read my article called: Greenware ceramics definition. What is a kiln? To learn more read my article called: What is a kiln used for?

What Is The Origin Of The Name Bisque Fire?

Did you know that potters use the phrase bisque fire to describe the first burning of clay? Clay is changed from raw Greenware clay to ceramic material during the bisque fire. A bisque fire produces ceramic ware that is firm and porous. That means it will absorb water if it becomes wet.

What Is The Composition?

Ceramic bisque, often known as biscuit, refers to the first kiln firing of raw dried clay. Earthenware ceramics is a porous clay bisque burned at a low temperature of around cone 04-06, or about 1850 degrees Fahrenheit.

What Is The Chemistry?

Kaolinite, often known as china clay, is a form of clay mineral that occurs naturally in the earth. It is an important industrial mineral that has a wide range of uses in various industries. Two layers of silica exist in this material: one is a tetrahedral sheet of silica that is related to the other by oxygen atoms and the other is an octahedral sheet of alumina that is joined to the other by oxygen atoms.

Bisqueware takes on the characteristics of a sponge at this point. The glaze will absorb the water and the item will be coated with a glaze after being dipped in the glaze. In general, the longer you let the bisque piece to soak in glaze, the more water it will absorb until the piece is completely soaked with glaze. It is then fired a second time, resulting in the formation of a ceramic substance.

Bisque is the first time that the clay is fired which is unlike unfired clay which has never been fired. Sometimes, the clay matures at a temperature higher than the glaze. If this is the case, the firing of bisque may be higher at temperature with the firing of a lower temperature glaze. As always the clay objects should be bone-dry before firing and should not be cold to the touch, indicating that they are not yet dry enough to fire. Occasionally, the bisque fire is called biscuit firing.

In the manufacture of ceramic and glass products, nepheline syenite is utilized as a filler material in place of feldspar, which is more expensive. Although cryptoperthite may be the feldspar found in nepheline syenite, it is also likely that it is an amalgamation of the feldspars albite and microcline. In some circumstances, sodalite or cancrinite can be used in place of nepheline, either wholly or in part.

Bisque firing or biscuit firing is the first time newly formed clay pots (unfired pottery, unfired clay) or greenware are subjected to high-temperature heating, usually in a kiln. Firing is done to vitrify, which means to render glasslike, so that a glaze may now be applied to the surface of the pottery.

Biscuit porcelain, also known as bisque porcelain or bisque, is an unglazed, white porcelain that has been processed as a finished product and has a matte look and feel. It was frequently employed in European ceramics, mostly for sculptural and ornamental items that were not intended for use as tableware and so did not require a protective glaze.

Bisque is clay that has been fired once but not glazed

Ed Shears

Can Bisqueware Be Glazed Or Painted?

Bisqueware is similar to unglazed earthenware that requires glazing and fired in a kiln. It’s too porous and soaks up glaze quickly. That is why it must be cured before applying another layer of paint.

The bisque firing is in the low temperature range removes water and carbon from the clay and thus fuses the clay pieces together. At this stage, you can no longer add water to the clay and reform the piece. The shape of the clay now has a set shape. The end result is the clay piece is hard, but it is also porous and able to absorb a small amount of water from a glaze solution. What this does is allows the glaze to adhere to the clay. Once this has been done the clay piece is ready for firing. This will melt and fuse the glaze together with the clay. The intermediate stage of bisque is when it’s intended to be glazed.

Is Bisque A Color That You Can See?

Biscuit porcelain, also known as bisque porcelain or bisque, is an unglazed, white porcelain that has been processed as a finished product and has a matte appearance and feel. It was commonly employed in European ceramics, mostly for sculptural and decorative artifacts that were not intended for use as tableware and hence did not require a protective glaze.

What Is Porcelain Bisque?

White unglazed porcelain is known as porcelain bisque or bisque. It is common in European pottery because soft marble has a comparable appearance. It has a matte texture and surface.

Ceramic Firing Techniques – Firing is a technique for creating ceramics that can withstand a lot of pressure. The firing takes place in a room with plenty of oxygen. There are two main ways for firing ceramics. The two ways are kilns and open firing. Firing is a critical stage in the ceramic process. It’s when clay changes from clay to functional pottery.

Biscuit porcelain, also known as bisque porcelain or bisque, is an unglazed, white porcelain that has been processed as a finished product and has a matte appearance and feel. It was commonly employed in European ceramics, mostly for sculptural and decorative artifacts that were not intended for use as tableware and hence did not require a protective glaze.

Now In It’s Final State

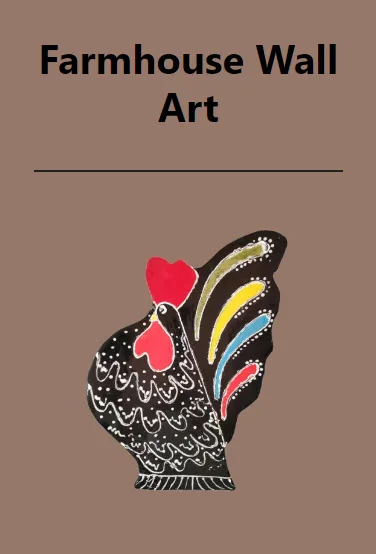

Looks a lot different now. Comparing the top image to this one the bisque is now in it’s final state and look much better. The brown and red colors really pop and add visual interest to the ceramic wall decor. Firing in the kiln and adding a little glaze makes a big difference.

Why Is It So Popular If It Isn’t Finished Or Complete?

This is a question I often get asked. It is desired because the artist knows he or she has passed the first stage, the first firing. The first test if you will. And it is very important because many things can go wrong during the first firing. In my opinion, it is the most critical stage because the clay is still full of water and is very susceptible to breakage. Just to recap, Bisqueware is artwork that has been fired once in the kiln and thus has undergone a ceramic change. This a chemical change where clay becomes ceramic. And as you know can never be re-used or returned back to its former state of Greenware. Bisqueware is still porous and therefore ready for glazing.

Clay has a mind of its own and has to be persuaded to conform to the artist’s shape. This technique is called compressing where the artist applies pressure to the clay achieving the desired results. But many times the clay fights back and does not conform to the shape. The result usually manifests during the first firing and the clay shows the artist who is boss by cracking or breaking. The artist has to know how far he or she can push the clay especially in vulnerable areas that are susceptible to cracking or problems. By applying pressure to the clay the artist causes the clay to be denser in that area.

So, at this point, the artist is very happy that his or her artwork is still intact and ready for the next stage where more glaze can be applied and that’s why it’s most desirable. I hope that answers your question and thanks for asking.

A ceramic artist is someone who produces ceramic objects or artwork. A ceramic artist is sometimes known as a ceramist. Someone who works with clay is referred to as a ceramicist, sculptor, potter, or simply artist. Ceramics are clay materials that, when fired, permanently alter their properties.

Raku Firing Technique – What Is Raku Firing Technique? – Raku firing is a type of low-temperature firing. While the pots are still hot and the glaze is still molten, the pottery is taken from the kiln. Stoneware clay is frequently used to make raku. Read the article to discover even more interesting facts about raku.

Ceramic or pottery may be divided into three categories: Earthenware, stoneware, and porcelain. However, you should read the entire essay since there are a few very interesting differences between the ceramic categories.

Handmade Ceramic Fish Wall Art – Colorful ceramic fish wall hanging.

Related Terms And Definitions

China Clay

Kaolinite, often known as china clay, is a type of clay mineral. It is a valuable industrial mineral with numerous applications. There are two layers of silica in this material, one of which is a tetrahedral sheet of silica that is joined to the other by oxygen atoms, and one of which is an octahedral sheet of alumina octahedral.

In addition to being a vital ingredient in the production of china and porcelain, they also used kaolin in the production of paper, rubber, paint, and a variety of other items. We also know kaolin as china clay.

Glaze

Glazes are made out of a combination of silica, fluxes, and aluminum oxide. Silica is the structural component of the glaze, and if heated to a high enough temperature (melting point), it can transform into glass. Because its melting temperature is too high for ceramic kilns, silica is coupled with fluxes, which are chemicals that prevent oxidation, in order to lower the melting temperature.

Six Types Of Clay Mined In The United States

- Kaolin (China clay) (High Kaolin content) – Kaolin is commonly used in the production of glossy paper. It’s also found in kaolin and morphine, a stomach pain reliever.

- Bentonite – Bentonite is used in a range of industrial applications, such as drilling mud and foundry sand, and it’s also used in pet waste absorbent products.

- Ball clay – Ball clay is a premium clay that is used in pottery, sanitary ware, roof tiles, ceramic tile, and wall and floor tiles.

- Fuller’s Earth – Pet waste products are also made with Fuller’s Earth.

- Fire clay – Fire clay is used in refractory bricks (used as a thermal insulator) and cement.

- Common Clay – Bricks, cement, and aggregate are all made from common clay.

What distinguishes ceramic from other materials?

- Electrical and thermal conductivity are both low.

- Melting points that are high.

- They don’t react with other compounds.

- They’re durable and long-lasting.

- Hardness and strength in spades.

Thermal Shock

A thermal shock is a form of mechanical force that occurs quickly. A mechanical load is defined as a load induced by a quick change in temperature at a specific place. It may also be used to a thermal gradient, in which various portions of an item expand at different rates.

Electric Kiln

An electric kiln is a high-temperature heating chamber used to convert materials. A kiln uses a method that has been around for thousands of years to harden ceramic bodies. When clay is heated (baking clay) to the right temperature, it becomes hard enough to create tiles and vessels. Glazes that are burned on top of the clay create permanent decorations.

Some electronic kilns have a scheduler that controls the firing schedule from beginning to end automatically.

Firing Schedule

It is the series of predetermined stages that the kiln proceeds through from the time it is turned on to the time it is either turned off or has cooled down enough to unload, which is referred to as the firing schedule. It is determined by changes in the kiln environment or the firing ramp that these transformations occur.

Gas Kiln

The most common form of fuel kiln nowadays is a gas kiln. Because they don’t require continual stoking and don’t produce unburned ash residue, gas kiln firing has become popular among contemporary potters and ceramic artists who want to employ fuel-burning kilns. Natural gas or propane are used to power most gas kilns.

Kiln Furniture

Kiln furniture is used in the creation of specific parts such as ceramic or metal components and is employed in the heating procedures of such items. Kiln furniture components are wearable elements that must be replaced on a regular basis because of the thermal, mechanical, and chemical stresses that occur during operation.

Clay Drying

Wet – This means that it has just come out of the bag. It is still capable of being manipulated and molded without suffering a significant fracture.

Leather firm – The clay has now become substantially stiffer than before. When the clay is bone dry, the color of the clay will become significantly lighter.

Metallic Glazes

Metallic Glazes have a glossy finish that ranges from shiny to matte, and they can transform commonplace surfaces into striking works of art. Metallic Glazes are ideal for usage as a Raku glaze because of their metal-like appearance and consistency.

Cone 06

Temp at 108F per hour ramp temp is commonly used for Bisque and Low fire glaze.

Leather Hard

The term “leather hard” refers to a certain stage of drying that occurs when a pot or other clay object is made. The clay is still obviously damp at this point, but it has dried sufficiently to be able to be handled without deforming during handling. The clay can be gouged or incised without breaking, but it will not take the impressions of the gouges or incisions. A further refinement of the leather hard stage can be achieved by dividing it into three stages: soft leather-hard, leather hard, and stiff leather hard.

Casting Slip

Casting, sometimes known as ‘slip casting,’ is a process that is most commonly utilized in the field of geopolymers because of its ease of application. In this process, complicated shapes are created from a suspension that is poured into a mold. When using geopolymers, the suspension is made up of raw ingredients in powder form that have been distributed in a liquid, which in this case is water.

Nepheline Syenite

In the creation of ceramic and glass products, nepheline syenite is used to replace feldspar as a filler material. It is possible that the feldspar in nepheline syenite is cryptoperthite, or that it is a combination of albite and microcline. Sodalite or cancrinite may be used in place of nepheline in some cases, either entirely or in part.

References

Strassel, R. M. (1968). A simple engobe developed for general studio use for wet and leather hard clay which may be adjusted with only minor changes to fit bone dry and bisque ware. https://pdxscholar.library.pdx.edu/open_access_etds/496/